Hardening strip steel, TBS band saw

Hardening strip steel

Our hardening strips are in the top class ranking in quality as well as quantity in the Steel Industry. We are giving various heat-treatment to strip of carbon tool steel, alloy steel, stainless steel and so on. And we are giving the mechanical properies most suitable for the material. By our integrated system of production from raw material to finished product, we will respond to the needs for greater sophistication and diversity from industrial equipment to ordinary products.

Outline

Features

- Heat treatment and processing that meet customer needs.

- Severe quality control

Main Applications

- Flexible die

- Band saw

- Shinai ruler

Main manufacturing products Grade, Chemical Composition, Main Applications

Tool steel

| Grade | Designation | C | Si | Mn | Ni | Cr | Mo | Others |

Main Applications |

| Carbon tool steel | YK4R | 0.98 | 0.25 | 0.43 | - | 0.15 | - | - | Valve, blade, sheet spring |

| YK5 | 0.85 | 0.22 | 0.35 | - | - | - | - | Bearing race, shinai ruler, sheet spring | |

| YK50 | 0.85 | 0.30 | 0.95 | - | 0.45 | - | - | Diaphragm, steel belt | |

| Alloy tool steel | SUBN11 | 0.80 | 0.20 | 0.40 | 1.10 | 0.30 | - | - | Band saw, round saw, blade |

| SUBN15 | 0.75 | 0.30 | 0.40 | 2.10 | 0.15 | - | - | ||

| SUBN21 | 0.78 | 0.20 | 0.70 | 1.75 | 0.25 | - | - | ||

| SKS7 | 1.13 | ≦0.35 | ≦0.50 | - | 0.40 | W2.1 | Saw | ||

| DC11 | 1.50 | ≦0.40 | ≦0.60 | - | 12.0 | 1.0 | V0.35 | Tool, blade | |

| DHA1 | 0.37 | 1.0 | 0.35 | - | 5.0 | 1.25 | V1.0 | Heat resisting disc spring, tool |

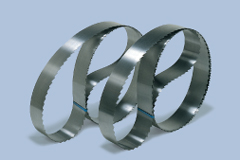

“TBS” band saw

“TBS” band saw blade is made of Daido's superior material with excellent technology. Our heat treatment technology ensures excellent flatness, stable straightness, homogenous surface, and reduces machining time remarkably. In order to meet sophisticated and diversified customer needs, we provide our customers a variety of sizes, tooth profiles with prompt delivery.

Outline

Features

- Excellent flatness, stable straightness, homogenous surface

- Reduces machining time remarkably

Main Applications

- Band saw

Main manufacturing products Grade, Chemical Composition

| Grade | Main chemical composition(%) | ||||

| C | Si | Mn | Ni | Cr | |

| SUBN11 | 0.80 | 0.20 | 0.40 | 1.10 | 0.30 |

| SUBN15 | 0.75 | 0.30 | 0.40 | 2.10 | 0.15 |

Dimensional accuracy and shape

| Edge | Square |

| Surface | Bright polished |

| Flatness | Width ≦0.1% |

| Thickness(mm) | BWG | Hardness |

| 0.80-1.20 | 21-19 | 434~460 HV(30) |

| 1.25-1.47 | 18-17 | 44.0~46.0 HRC |

| 1.65-1.98 | 16-[0.078] | 43.0~45.0 HRC |

| 2.11-3.05 | 11-14 | 42.0~44.0 HRC |

Various tooth profiles are available.

We are able to provide you products of your size as per request.

(available dimensions: [size:width≦8-1/8inch(203mm) ,thickness≦17BWG(1.45mm)]

| S type |

For 4-6inch-wide band saw blades; standard type in Japan |

|

| N type | Mainly for wider band saw blades for large-diameter logs |

|

| M type | With large-area gullets; suitable |

|

| Grade:SUBN15 | ||

| mm | BWG | |

| 1.45 |

156 181 206 232 260 |

6-1/8 X 17 7-1/8 X 17 8-1/8 X 17 9-1/8 X 17 10-1/4 X 17 |

| 1.65 |

181 206 232 260 286 311 |

7-1/8 X 16 8-1/8 X 16 9-1/8 X 16 10-1/8 X 16 11-1/8 X 16 12-1/8 X 16 |

| 1.83 |

206 232 260 286 311 362 |

8-1/8 X 15 9-1/8 X 15 10-1/8 X 15 11-1/8 X 15 12-1/8 X 15 14-1/8 X 15 |

| 1.98 |

260 286 311 |

10-1/4 X 0.078 11-1/4 X 0.078 12-1/4 X 0.078 |

| 2.11 |

260 286 311 337 362 |

10-1/4 X 14 11-1/4 X 14 12-1/4 X 14 13-1/4 X 14 14-1/4 X 14 |

| 2.26 |

311 362 |

12-1/4 X 0.089 14-1/4 X 0.089 |

| 2.41 |

311 337 362 387 413 |

12-1/4 X 13 13-1/4 X 13 14-1/4 X 13 15-1/4 X 13 16-1/4 X 13 |

| 2.77 |

362 387 413 |

14-1/4 X 12 15-1/4 X 12 16-1/4 X 12 |

| 3.05 | 413 | 16-1/4 X 11 |

| Grade:SUBN11 | ||

| mm | BWG | |

| 0.80 |

76 80 102 |

4 X 21 |

| 0.89 |

51 76 102 127 |

2 X 20 3 X 20 4 X 20 5 X 20 |

| 1 |

80 90 |

|

| 1.05 |

102 127 |

4 X 19 5 X 19 |

| 1.1 |

100 110 120 |

|

| 1.2 |

80 85 100 120 |

|

| 1.25 |

102 114 127 152 178 203 |

4 X 18 4-1/2 X 18 5 X 18 6 X 18 7 X 18 8 X 18 |

- Other sizes: to be inquired

We will contact you after confirming the contents.