Environmental equipment

Ash melting system

Land fill sites for incinerated ash are hard to secure these days. DAIDO has developed DAP, the first of its kind in the world, which is based on the arc melting process.

DAP has succeeded in making the volume of incinerated ash smaller, turning the refuse into a less polluting substance, and then recycling it.

- Adopted in many refuse incineration facilities. Holds the top market share in Japan.

- Uses the necessary energy recovered from the heat produced in the process of refuse incineration for electricity.

- Melts the incinerated ash in the arc melting furnace and converts it into sandy slags. The slags are used for the base layer of paved roads, tiles, and bricks, in an attempt to recycle refuse.

System flow chart

Daido Oxygen-burning process-DOP (Ash melting system by oxygen burner)

Ash melting system by oxygen burner is the most suited to melt the ash from stoker type incinerator and fluid bed of MSW and RDF.

-

- Melting ash perfectly

- After the ash is melted in the flame of oxygen burner at over 1,600℃, and though the furnace bottom pool, melted slag is discharged and water-quenched continuously. On this way, dioxins is decomposed in high percentage.

-

- Low running cost

- Fuel consumption is less than half as compared with conventional burner surface melting. It is possible to adopt in the plant without waste-to-energy facilities.

-

- Saving space

- As high efficiency of treatment in flame, furnace is very compact and setting space is minimum. As a result, it is most appropriate to maintenance the existing plant.

-

- Stabilization

- With the know-how of mixed ash (bottom ash and fly ash) melting technology by electric arc furnace, the successful and operation is possible to realize long refractory life and maintain harmless exhaust gas.

System flow chart

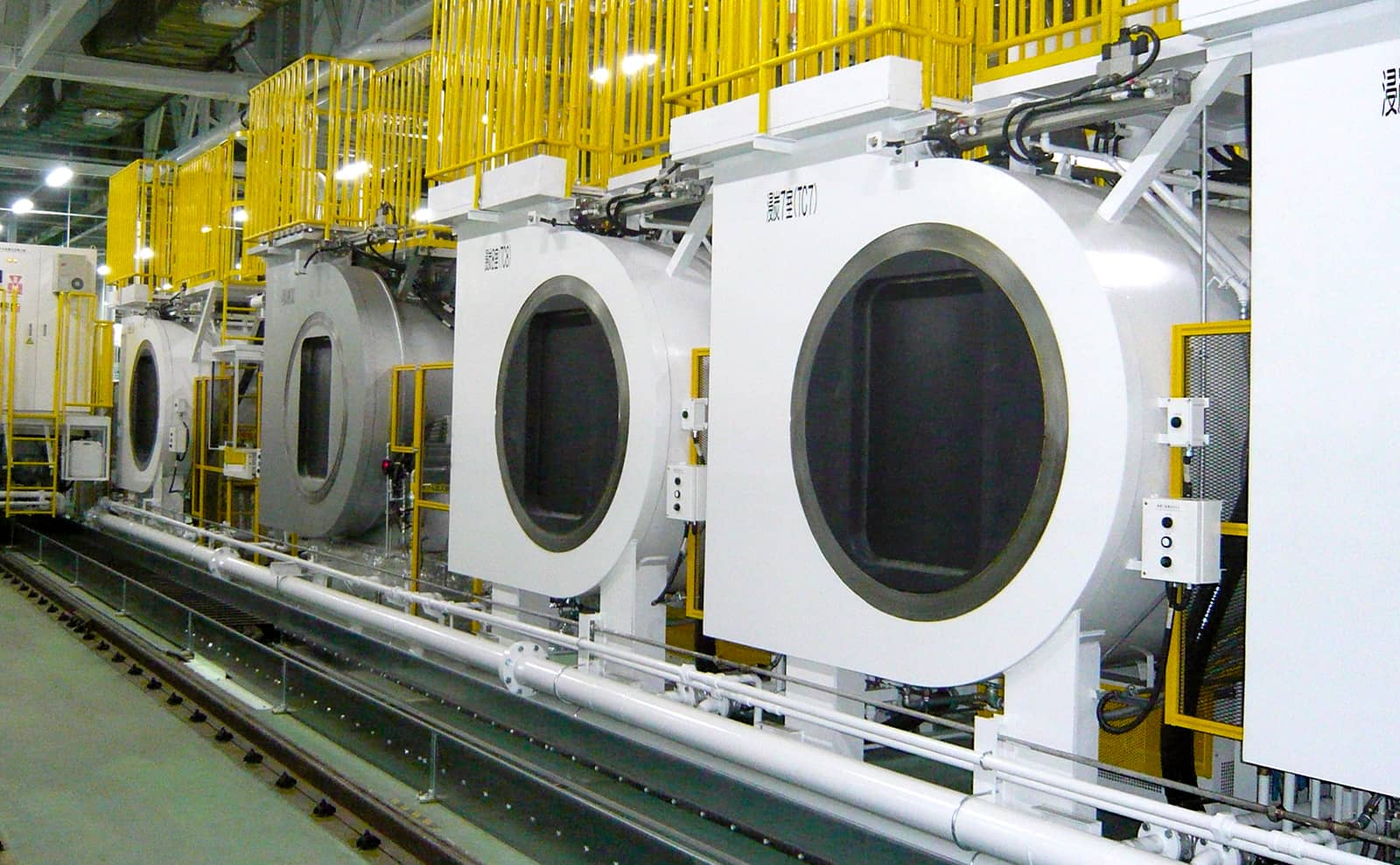

Sewage sludge carbonizing system

As remarkable progress of sewage projects, the sewage sludge treatment method has now reached an important turning point. Until today we have relied upon reducing sewage which simply results in using less land for disposing of the sewage. Now we are giving our top priority to recycling and creating resources.

DAIDO STEEL has developed a technology to produce charcoal (carbonized sewage sludge) from the sewage sludge.

- Having similar properties to those of natural charcoal, carbonized sewage sludge has many uses and will greatly help to promote using sewage sludge as a resource.

- By adopting a rotary kiln carbonization furnace with external heating, we are able to re-use pyrolysis gas produced from the sewage sludge for heating and producing carbonized products which offer both stable properties and form.

Main applications of carbonized sewage sludge

Gardening materials

Soil improvement materials

Snow fluxing agents

Dehydarating agenets

deodarants

composting materials

Solid fuels, etc.

System flow chart

Dust recycle

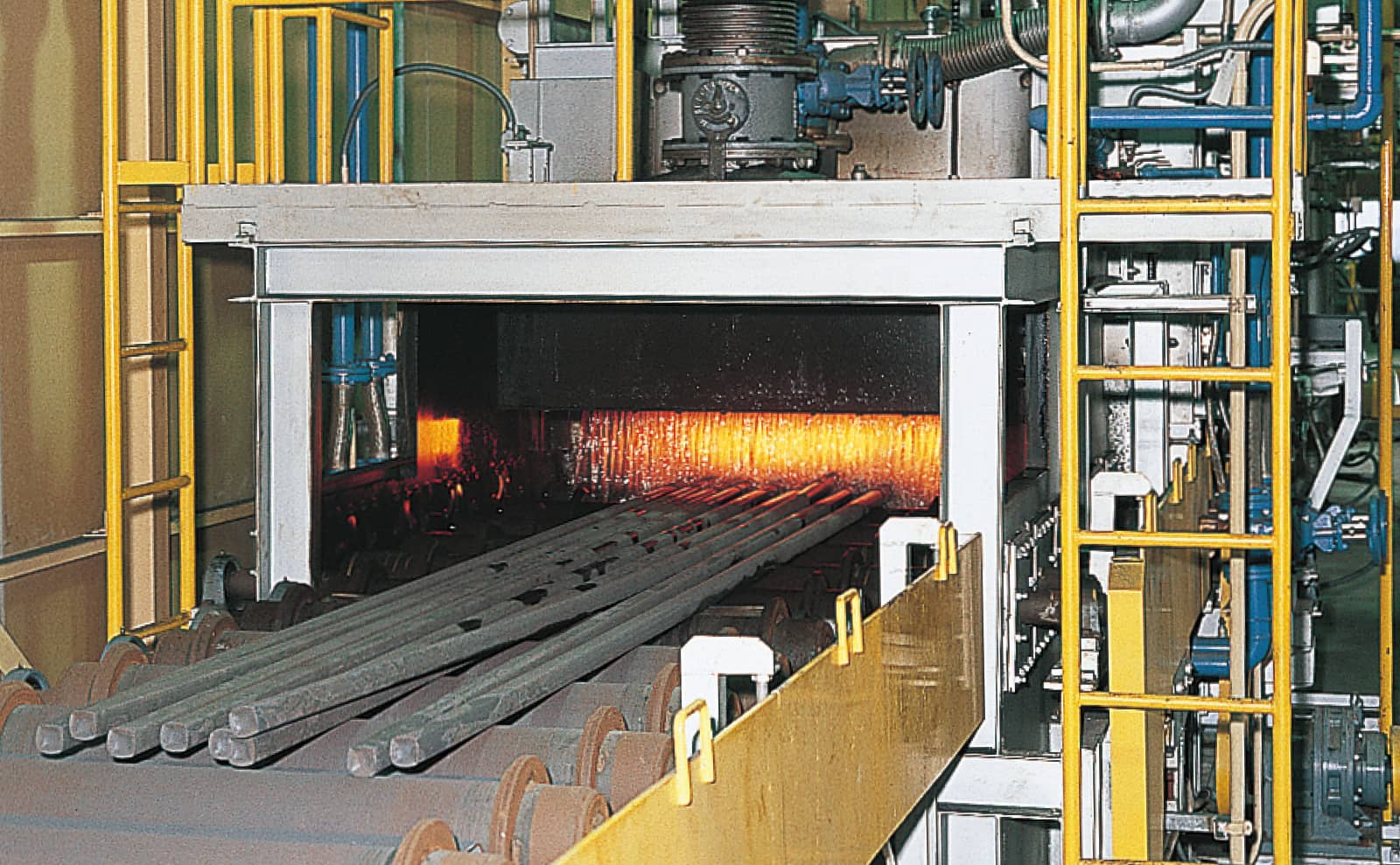

INMETCO process

- This is the system which has been developed and operated by the American company, INMETCO; after kneading and pelletizing of metal powder and reducing material powder, the rotary hearth furnace is used for direct reduction to produce direct reduced iron.

- The system is able of treating the dust of the blast furnace, converter and electric furnace, mill scale, and sludge, so that it will contribute greatly to the environmental protection and recycles of resources.

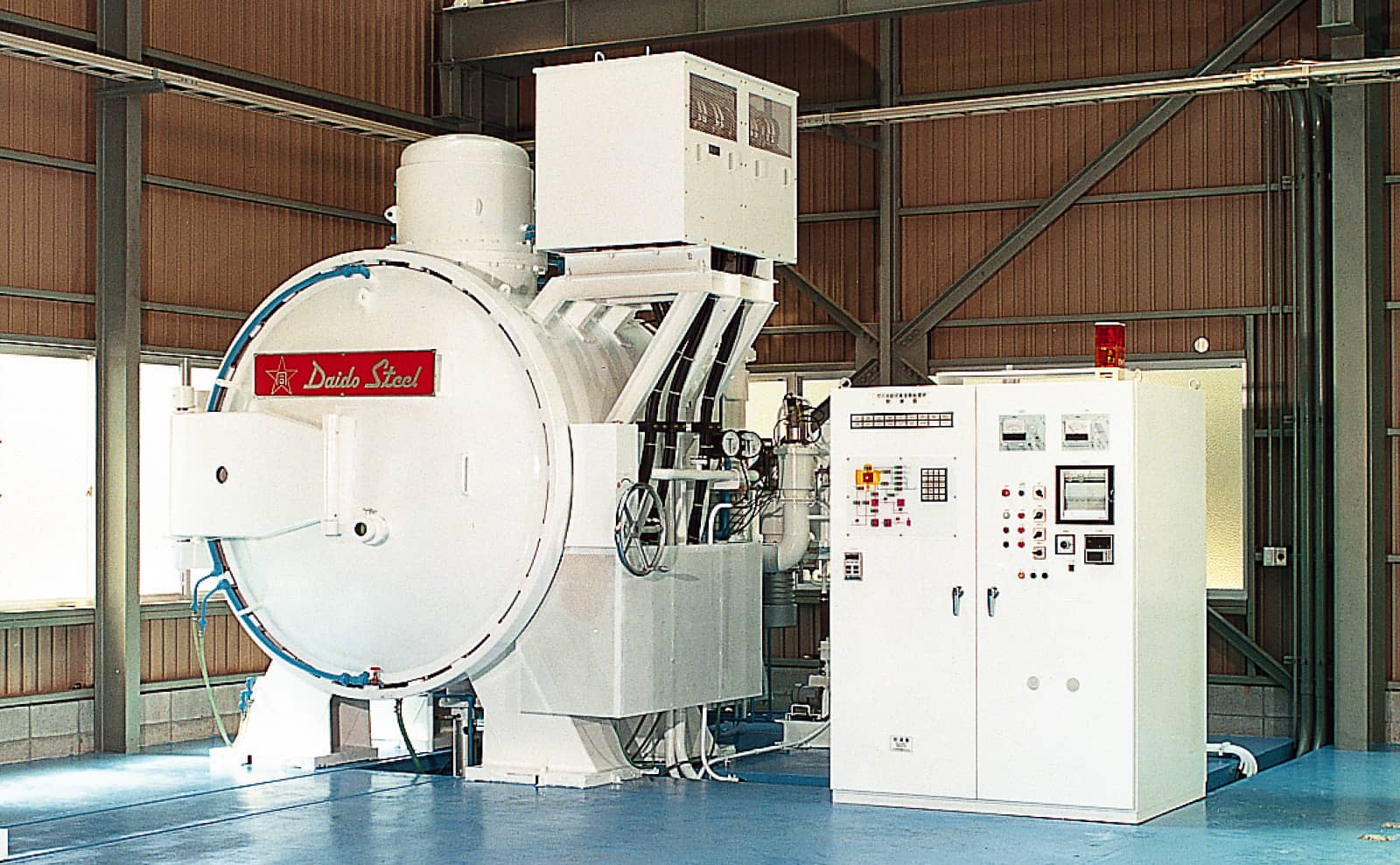

DSM (Daido Special Recycling Process for Dust and Slag Melting)

- As dust and slag is melted down completely at high temperature, it is very effective against dioxin.

- Produced valuable substances are completely harmless and can meet all environmental standards.

- More than 99% of dioxin can be removed by high temperature treatment in the furnace and strong rapid cooling mechanism.

- Besides electrical furnace dust and reduced slag, it is expected that this system will be applied to other waste treatments.

- The equipment is simple and compact because of unnecessary pretreatment such as dust granulation and so forth.

- Through simple design, excels in operability and suitable for on-site processing.

System flow chart

Environmental equipment for tunnel

Tunnel filter

- Eliminates dust from the exhaust gas in road tunnels through a large filter of a ventiration system. Holds the leading market share in Japan.

- The filter medium has a long service life and is automatically cleaned and reused. Almost no maintenance is required.

Electrical dust collector for automobile tunnel

- his is the system in which the dust in exhaust gas is charozzle for unit cleaning and ged to suction and collect efficiently to the dust collecting electrodes by static electricity.

- The electric dust collector is equipped with the cleaning ncarries out automatic cleaning according to the instructions of the dust collecting control panel.

Steep sloped electromagnetic filter

- A water tereatment system which separates and removes magnetic particles in waste water by use of an electromagnet.

- A new sustem which will replace coagulation settling and sand filtration by having a filtration rate of more than 10 times that of sand filtration.