Font Size

Heat treatment furnaces

Products list

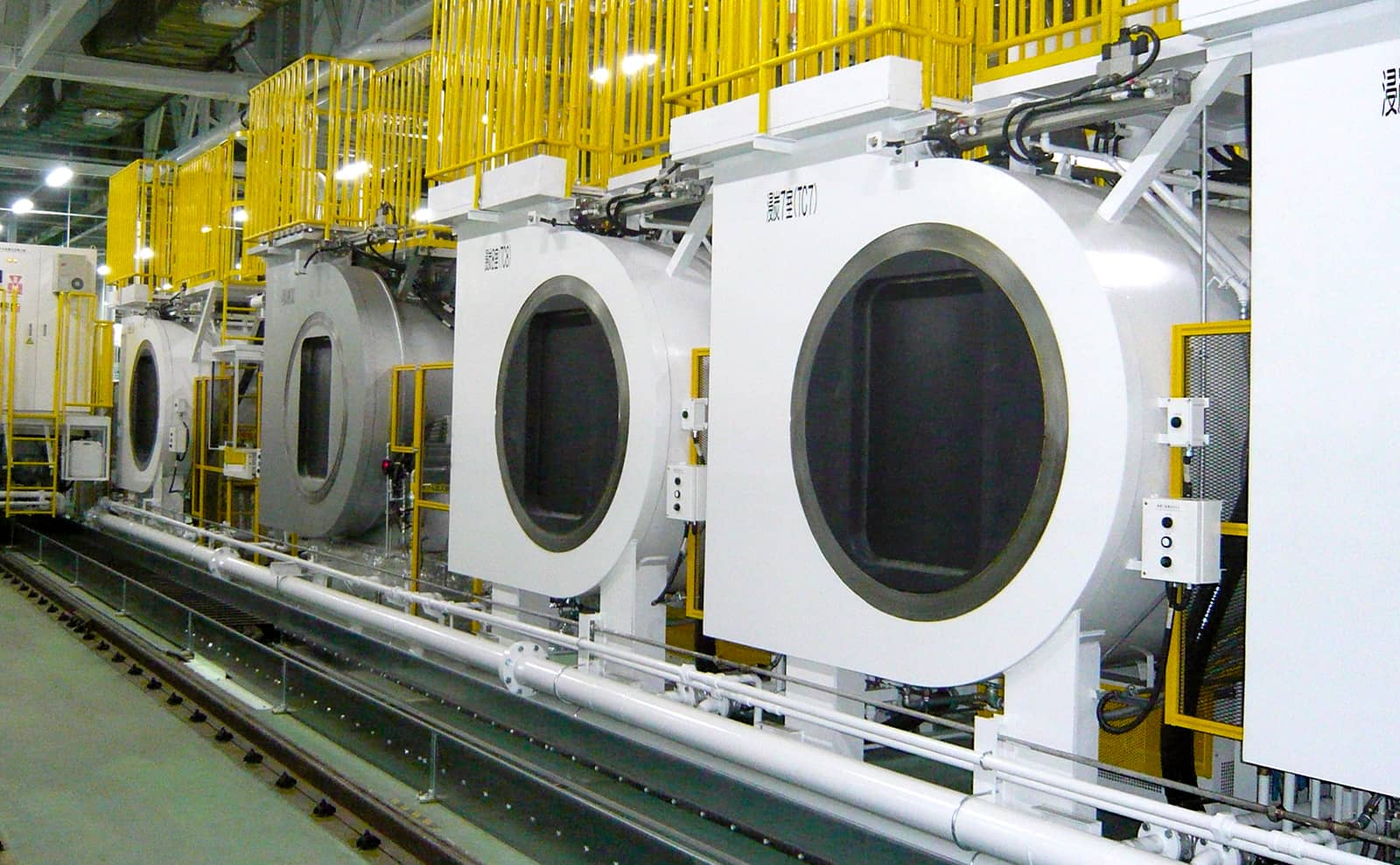

High reliable furnaces for copper and aluminum

Roller hearth continuous annealing furnace

- Designed for continuous annealing to achieve high productivity, energy efficiency, and unmanned operation.

- Improves heat efficiency and acid descaling efficiency by use of rapid heating/cooling technology.

Roller hearth solution treatment furnace

- Achieves substantial energy and manpower conservation by recovery of exhaust gas and by utilizing DAIDO PERM(permeable energy radiative media) on te ceiling of preheating chamber.

Roller hearth non oxidizing annealing furnace

- Designed for spheroidizing annealing of various cold forged products. Provides stable transportation . Simplifies maintenance.

- Achieved drastic energy conservation by utilizing light weight insulation material, recuperator, and protective gas generating reaction heat usage(built-in type).

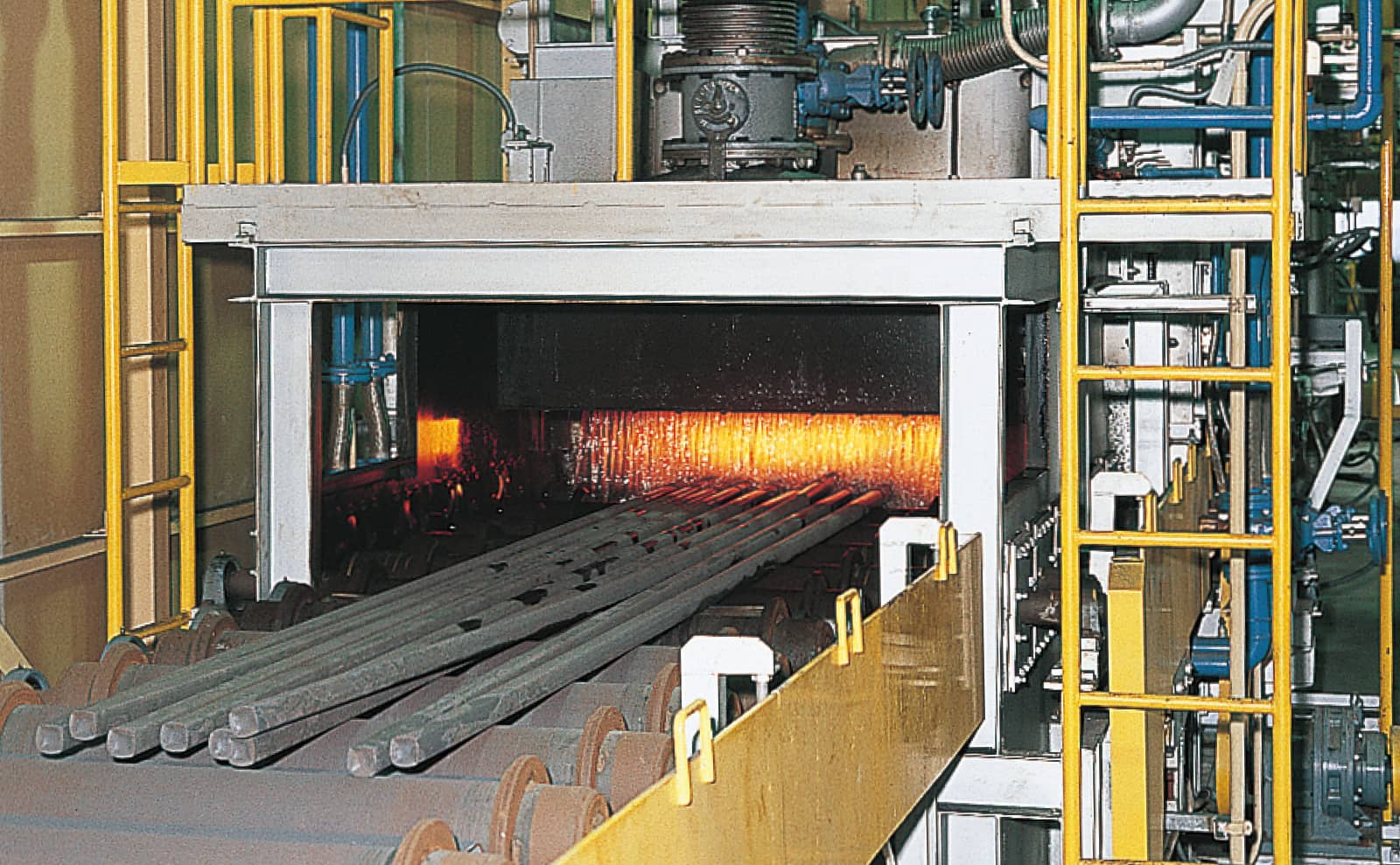

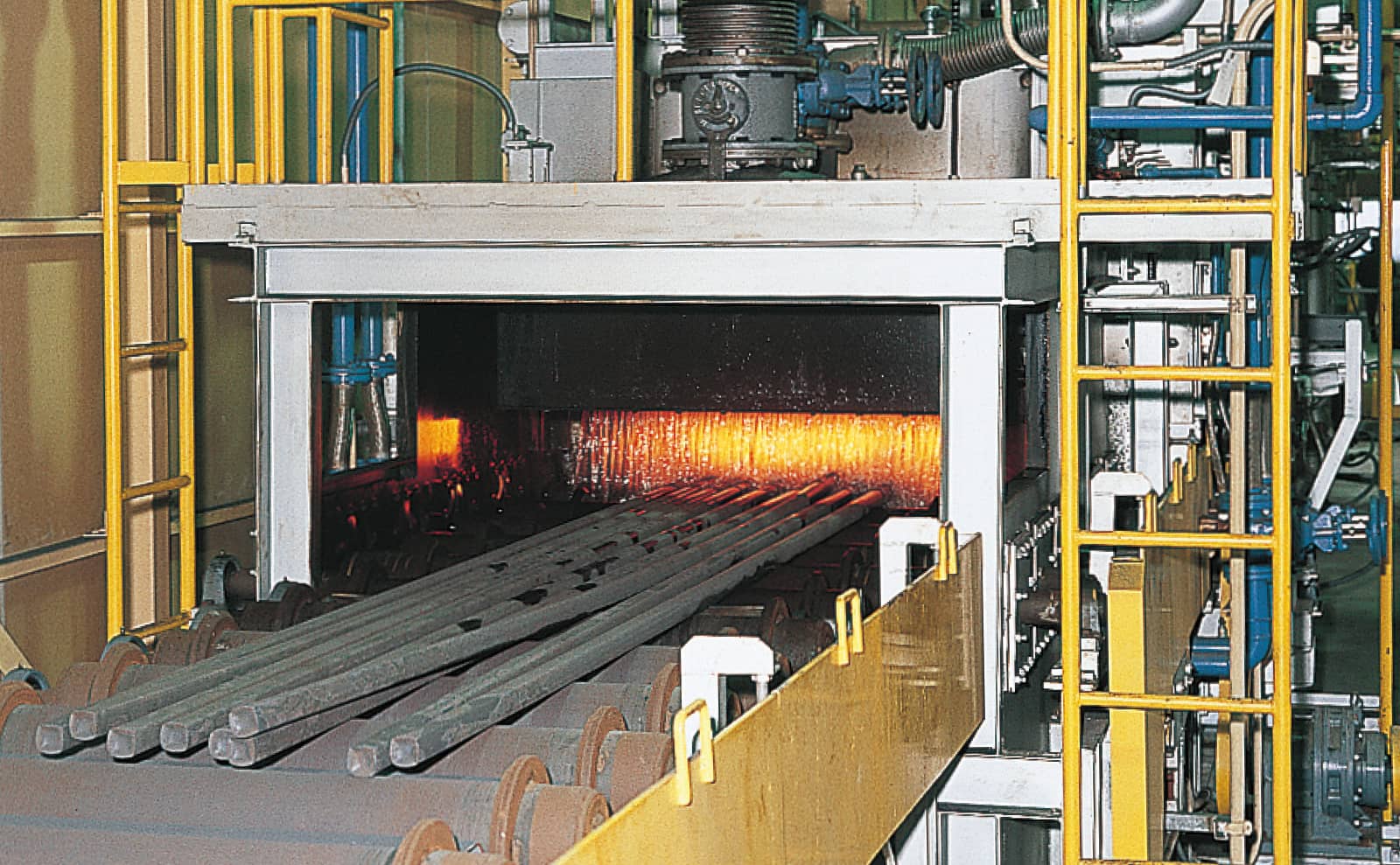

Self-heat annealing furnace

- Energy saving furnace that uses residual heat of forged products.

- Enables cost reduction in material handling and integration of the shot-blasting process into the same line..

Motor core / Transformer core annealing furnace

- Fully automated operation from degreasing of motor core, annealing to blueing; just set the parts on the table. The BA furnace for annealing of transformer core is also available.

- Effectively removes oil under vacuum pressure reduction after pre-heating to prevent sticking. (With a vacuum purging chamber)

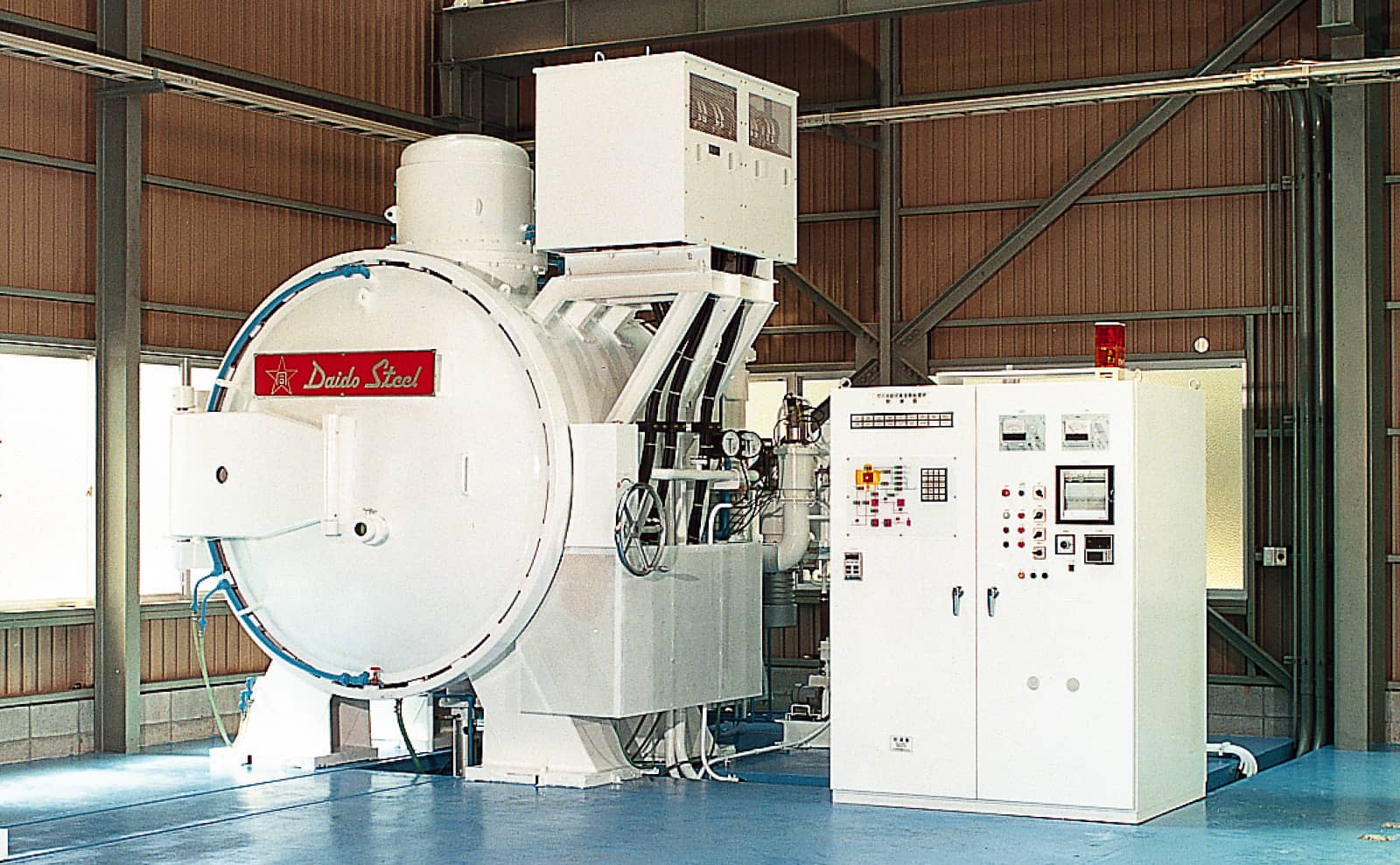

Bright annealing furnace for copper tube with automatic purging system

- Automatically performs purging by exothermic gas for non-oxidation inside the tube at charging table, and purging back to dry air or N2 gas at discharging table.

- Provided with the automatic purging function; exothermic gas in the heating chamber purges the inside of the tube to remove vaporized oil.

Copper and copper alloy floating annealing furnace

- By adopting a waveform tracking system, stable float tracking maybe obtained that dose not cause wrinkles or flaws, resulting in uniform heating.

- Can process strips 0.035-1.7mmthick.

Aluminum melting and holding furnace

- Provides high-speed melting through use of a high velocity burner and minimizes oxidation losses by computer control.

- Allows any combination of stationary, slanted moving, circular and rectangular furnaces.

Aluminum floating annealing furnace

- Employment of the waveform tracking system enables stable float tracking and uniform heating that does not cause wrinkles of flaws.

- Can process strips as wide as 2100mm.

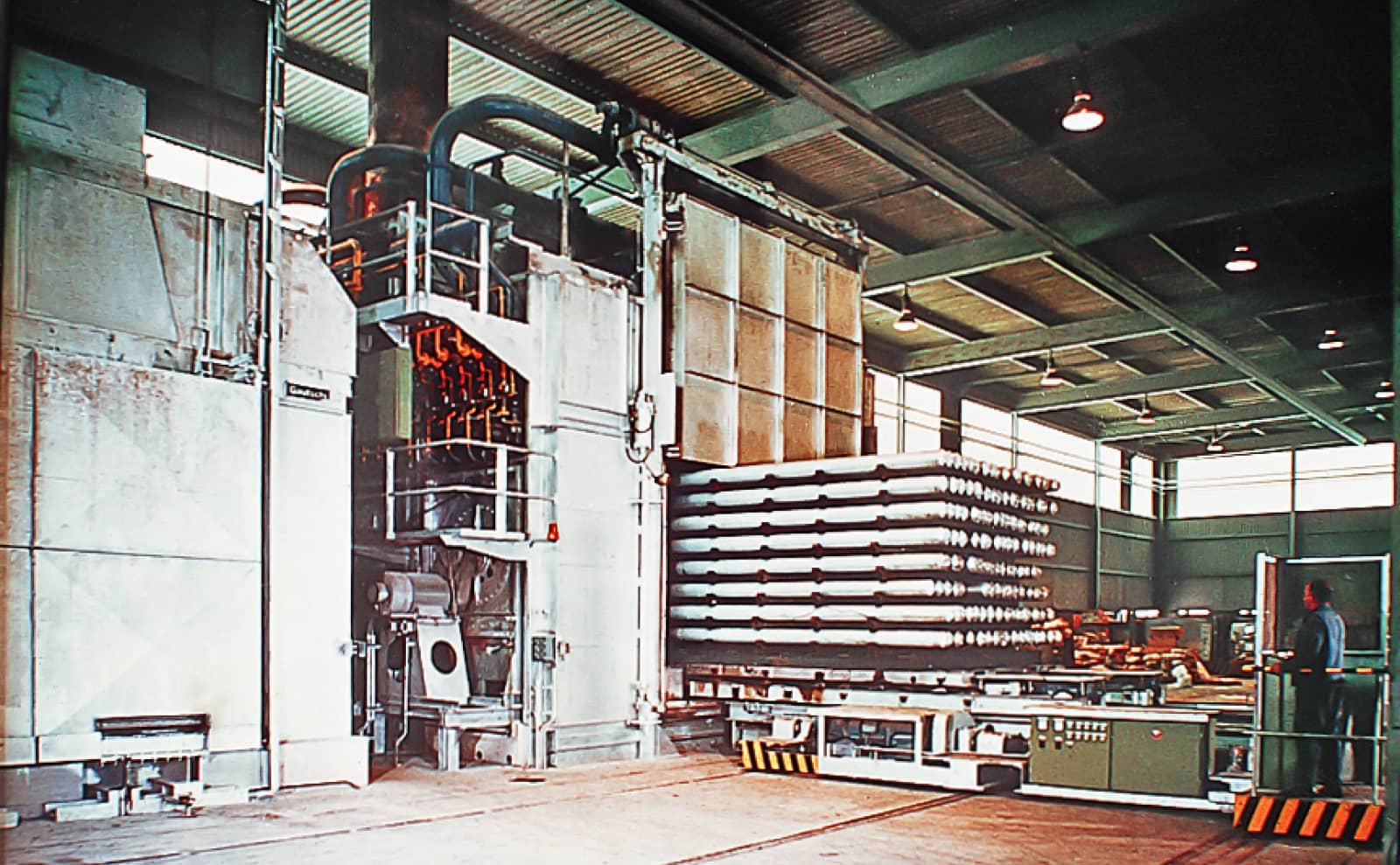

Aluminum ingot heating furnace

- Productivity will be improved by realization of rapid heating through adoption of large capacity hot air circulation fan, the special nozzle on the furnace floor, and alike, which were developed by our company.

- No damage transfer is realized by the adoption of special metal slide shoe (patent of Gautschi.), mechanical-shock-less handling, etc.

Aluminum billet homogenizing furnace

- The furnace temperature distribution will be improved by means of the best hot air circulation.

- Heating time will be improved by the adoption of high efficiency and large capacity hot air circulation fan.

Aluminum coil annealing furnace

- Energy saving and low Nox are realized by combination of P-letter shaped radiant tube burner and recuperator built-in burner.

- Temperature up time is reduced by high convection heat transfer to the coil end surface.