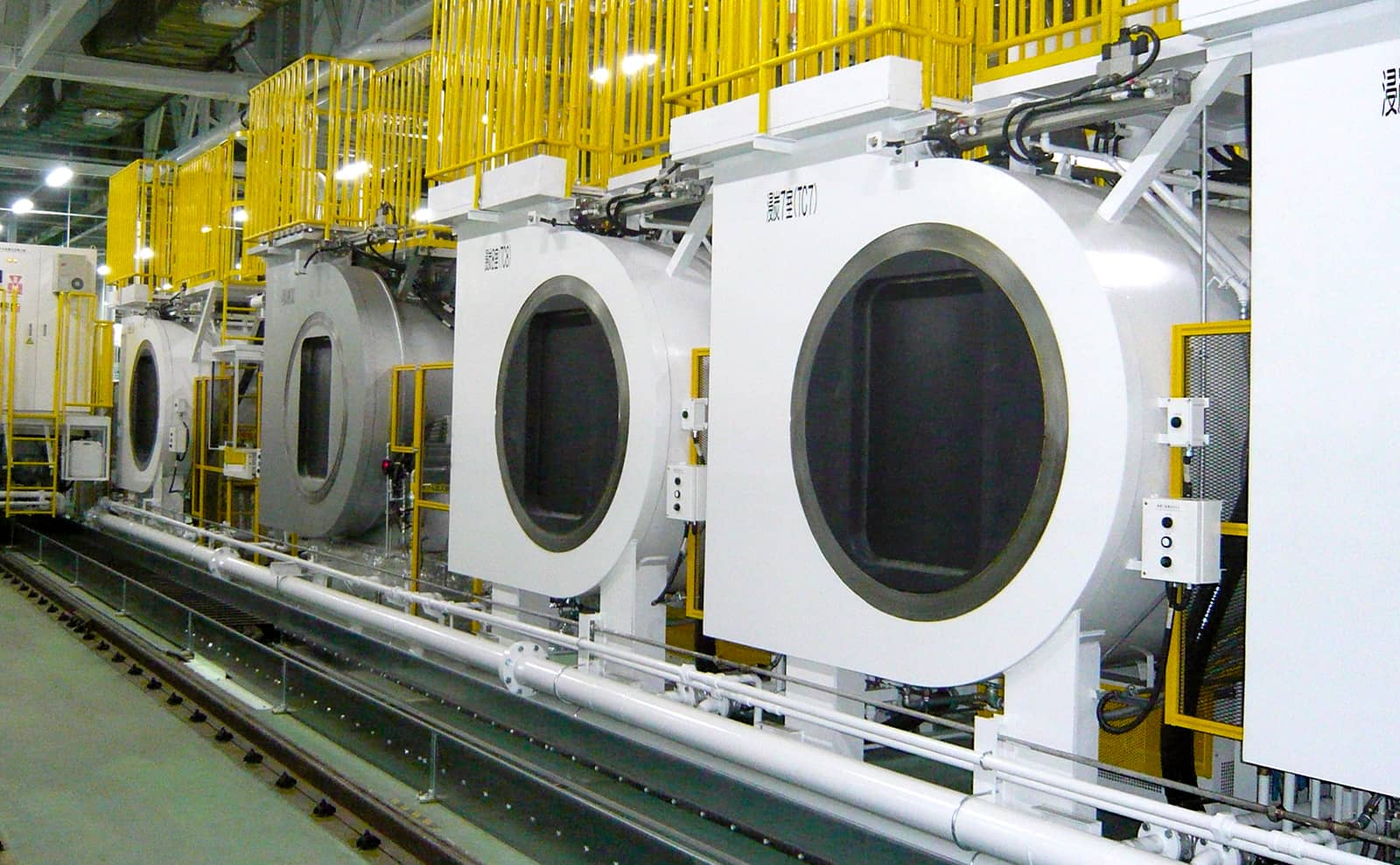

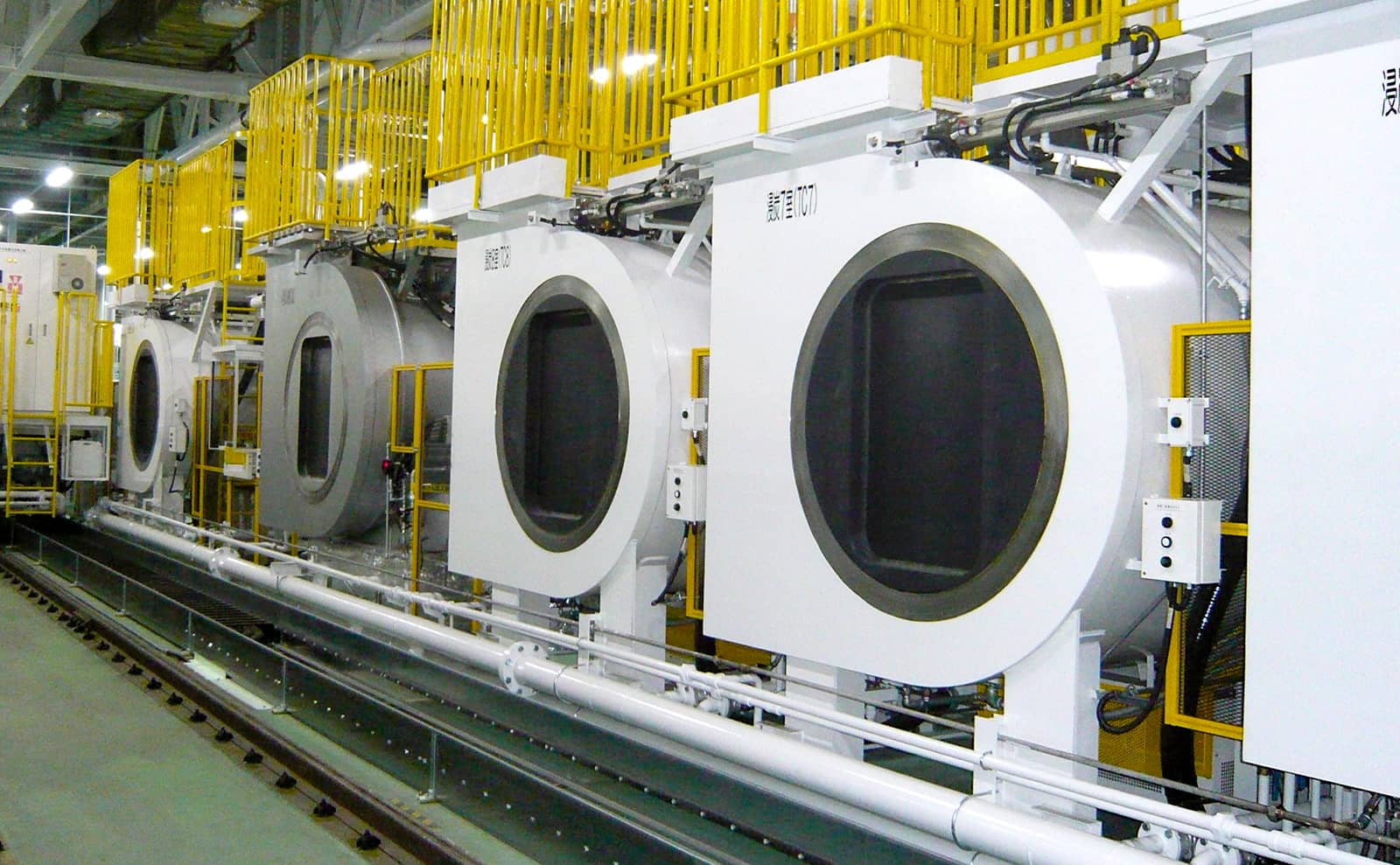

Vacuum carburizing furnace ModulTherm®

47% reduction of discharge of CO2 and tripled productivity are proved (compared with the gas carburizing furnace)

This is the vacuum carburizing furnace, ModulTherm®, which combines our company’s technology of steel material and vacuum heating treatment technology and the vacuum carburizing technology of German ALD Co., Ltd. The technology has a merit that rapid, high accuracy and stable heat treatment quality for vacuum carburizing can be offered when carburizing automobile parts, in which strength and durability are required. In the case of introduction of the system, 47% reduction of discharge of CO2 and tripled productivity are proved compared with gas carburizing furnace. This is eco solution ModuTherm that can result in great effect in taking measures for global warming.

Features

-

Denatured gas is not usedVacuum carburizing does not use a large volume of denatured gas like gas carburizing, so only a small volume of surplus gas is discharged outside the furnace. High efficiency carburizing is possible with only a small volume of acetylene gas.

-

Stand-bye energy is less and safety personnel is not requiredWhile gas carburizing requires constant supply of gas for maintaining furnace temperature and atmosphere, energy consumption of vacuum carburizing during non-operation is extremely small and only about one hour is required for start-up. It is possible to save stand-by energy and safety personnel during non-operation.

-

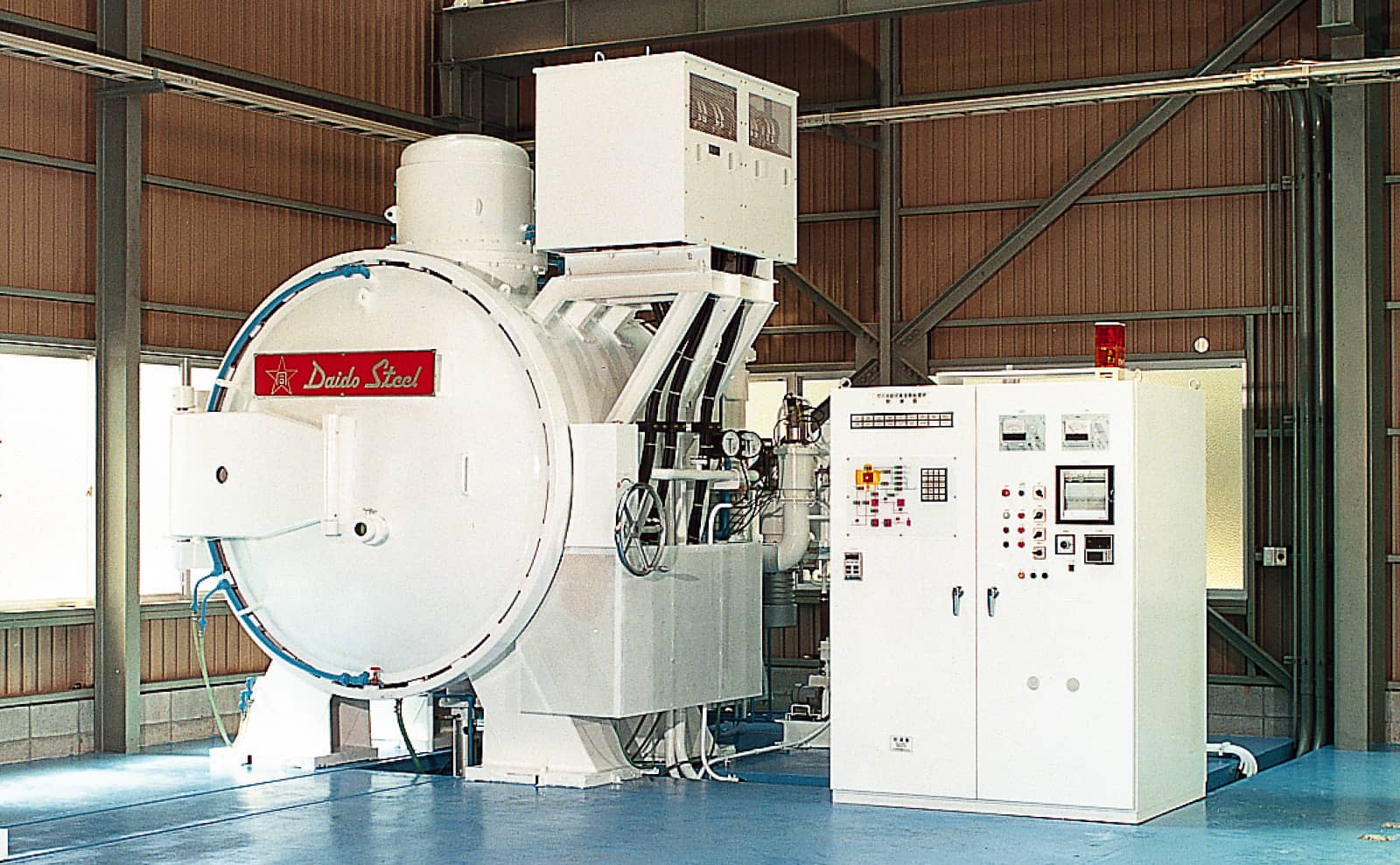

The furnace for prior evaluation is availableIt is possible to get the requirements for volume production furnace by using the actual furnace for volume production, which is installed in the company before installation. It will contribute to the smooth start of the furnace of the customer. The basic layout of the demonstration furnace.

-

Development of the steel materials for vacuum carburizingThe “DEG Steel” is developed, which is suitable for preventing the generation of surplus carburizing materials such as those on the gear end, and so on. It is possible to strengthen dramatically the automobile parts.

47% reduction of CO2 discharge (compared with gas carburizing)

The loss of the furnace atmosphere gas is very small

It is not necessary to correspond to the time during non-operation

- It is proved that the original unit of CO2 per production can be reduced about 47% in a case of introduction

Three times productivity(compared with gas carburizing)

|

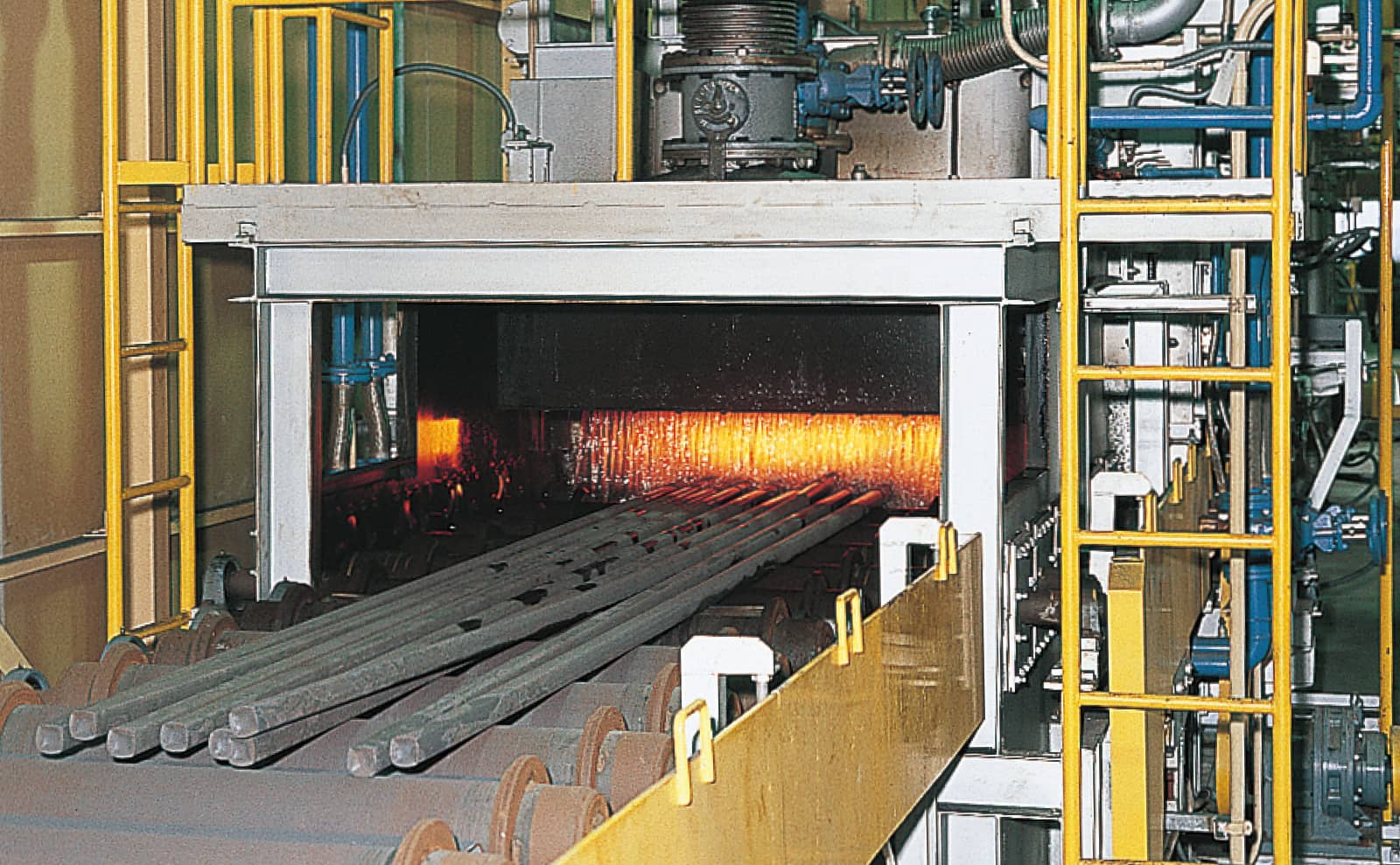

Gas carburizing furnace (4 units) |

ModulTherm® (1 unit 10 rooms) |

|

| Production/day | 19.2tons | 28.8tons |

| Number of personnel/day | 6 persons | 3persons |

| Productivity/person | 3.2tons | 9.6tons |

- The safe and comfortable ModulTherm® without flame and heat will result in high efficiency production with minimum operating staffs.

- The energy loss at the time of variation of production can be reduced more than continuous furnace by the system configuration which is modularized.

- It is possible to reduce greatly the load of conditioning work by means of carburizing condition setting software, which is attached to the equipment.