High Alloyed Powder

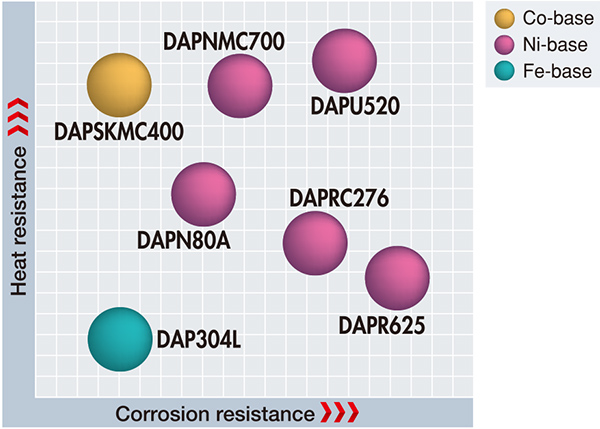

Nickel- and cobalt-based high alloyed powder.

Excellent in heat, corrosion and wear resistance.

Applicable to sintering, MIM, HIP materials, thermal spraying and welding alloy.

Features

- Nickel-based alloy:High heat and corrosion

- Cobalt-based alloy:High wear resistance

- Particle shape and size are adjustable in accordance with customer's manufacturing processes and applications.

- Can be mixed with iron-based alloy powder and other materials as hard particles to improve the wear resistance of sintered parts.

- In response to characteristic requirements, optimal material is selectable.

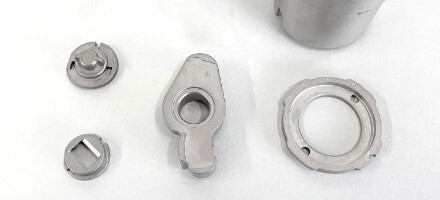

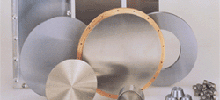

Main applications

- Valve seat

- Chemical engineering equipment

- Jig for heating furnace

- Turbine blade

- Mesh belt

- Turbo charger parts

- Bush

- Plant equipment

Main powder products

| Material | Chemical Composition(mass%) |

Corresponding material type |

Characteristics | ||||||||

| C | Si | Ni | Cr | Mo | W | Co | Fe | Others | |||

| DAPSKMC400 | - | 2.5 | - | 8 | 28 | - | Bal. | - | - | T-400 | High heat and wear resistance |

| DAPNMC700 | - | 3.0 | Bal. | 15 | 32 | - | - | - | - | - | High heat and wear resistance |

| DAPRC276 | - | - | Bal. | 16 | 16 | 4.0 | - | 5 | - |

|

High corrosion resistance against oxidizing or reducing atmosphere |

| DAPR625 | - | - | Bal. | 21 | 9 | - | - | - | Nb,Ti,Al | DSALOY625 | High strength and corrosion resistance |

| DAPN80A | 0.10 | - | Bal. | 20 | - | - | - | - | Al,Ti | - | High creep and fatigue strength at elevated temperature |

| DAPU520 | 0.04 | - | Bal. | 19 | 6 | 1.0 | 12 | - | Al,Ti,B | DSALOYU-520 | High strength and high heat resistance at elevated temperature |

| DAPR760 | - | - | Bal. | 38 | - | - | - | - | Al | DSA760*1 | High hardness and corrosion resistance |

| DAPSKH51 | 0.85 | - | - | 4 | 5 | 6.5 | - | Bal. | V | SKH51 | High wear resistance |

*1 Developed steel by Daido

※We can also produce metal powders of chemical compositions not listed in this table. Please contact us.