Powder for Welding / Brazing

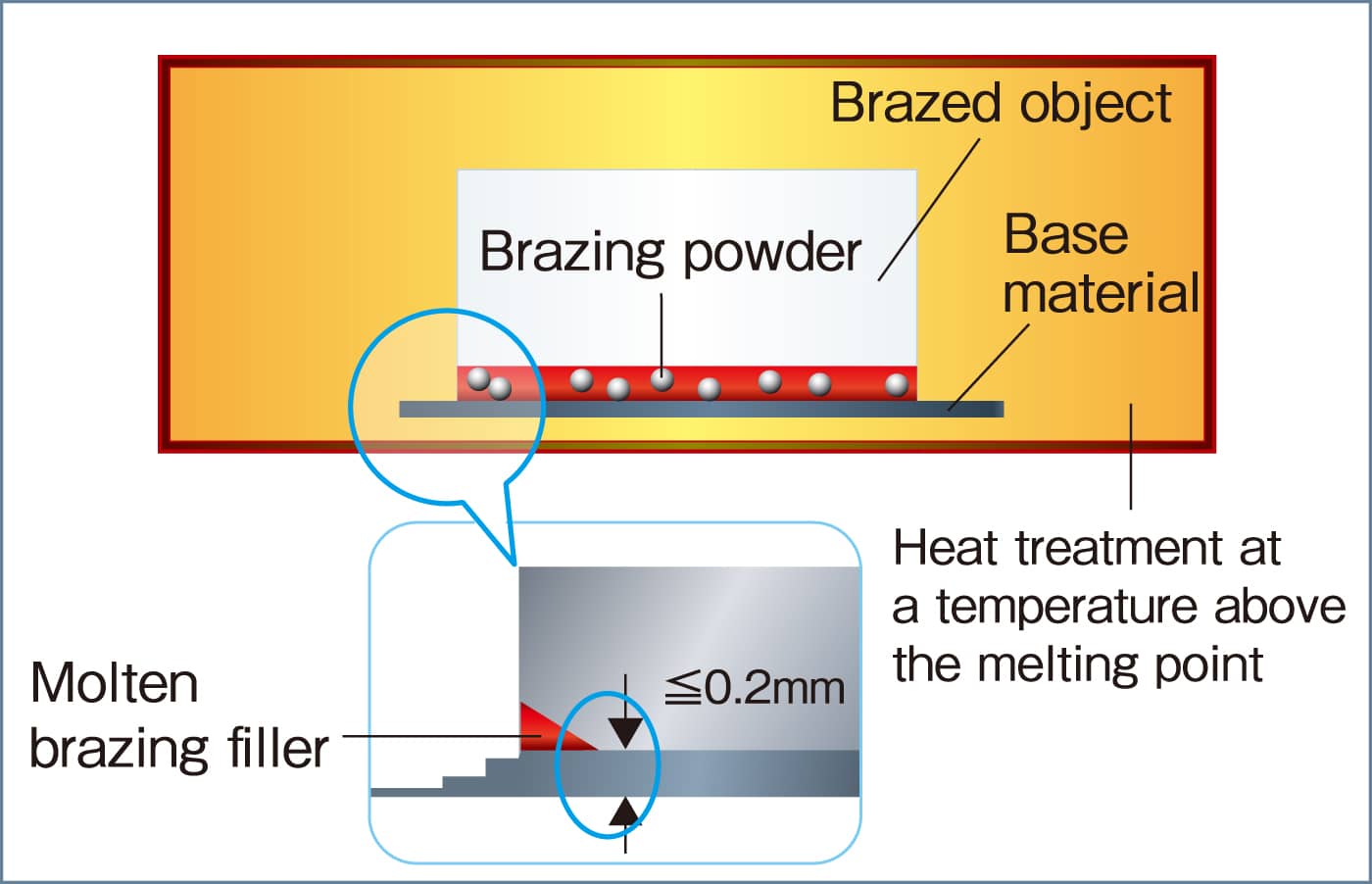

Spherical metal powder which has high quality and high fluidity with low oxygen content

Can be used for surface-hardening welding, brazing,etc.

Features

- Spherical, high-fluidity and low-oxygen metal powder produced by gas atomization.

- Particle shape and size are adjustable in accordance with customer's manufacturing process and application.

Welding(PTA and leser-cladding, Thermal spraying, Brazing)

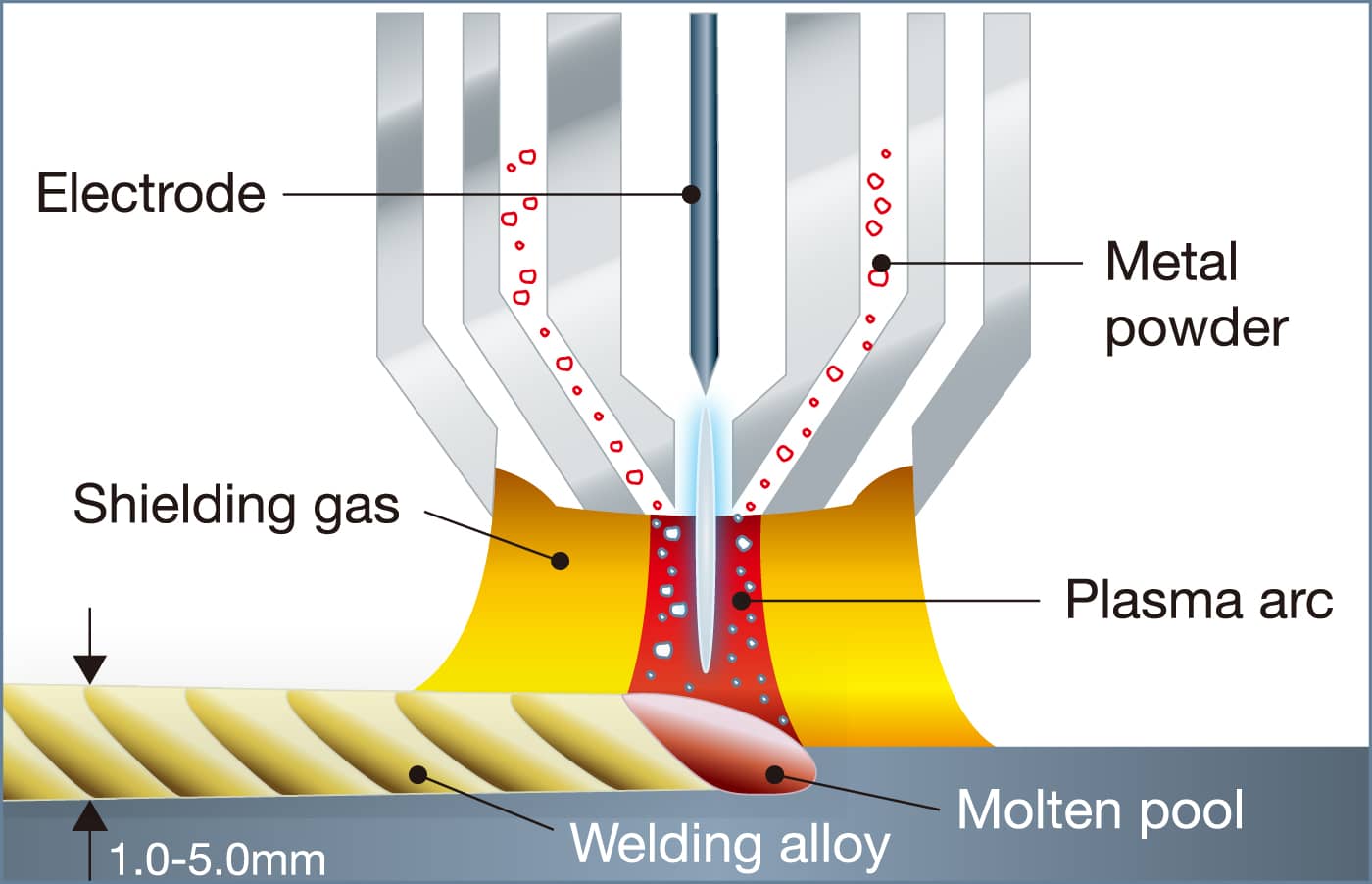

【 PTA and laser-cladding 】

- Engine valve

- Mill roll

- Forging die and punch

- Jigs for heating furnace

- Parts of injection molding equipment

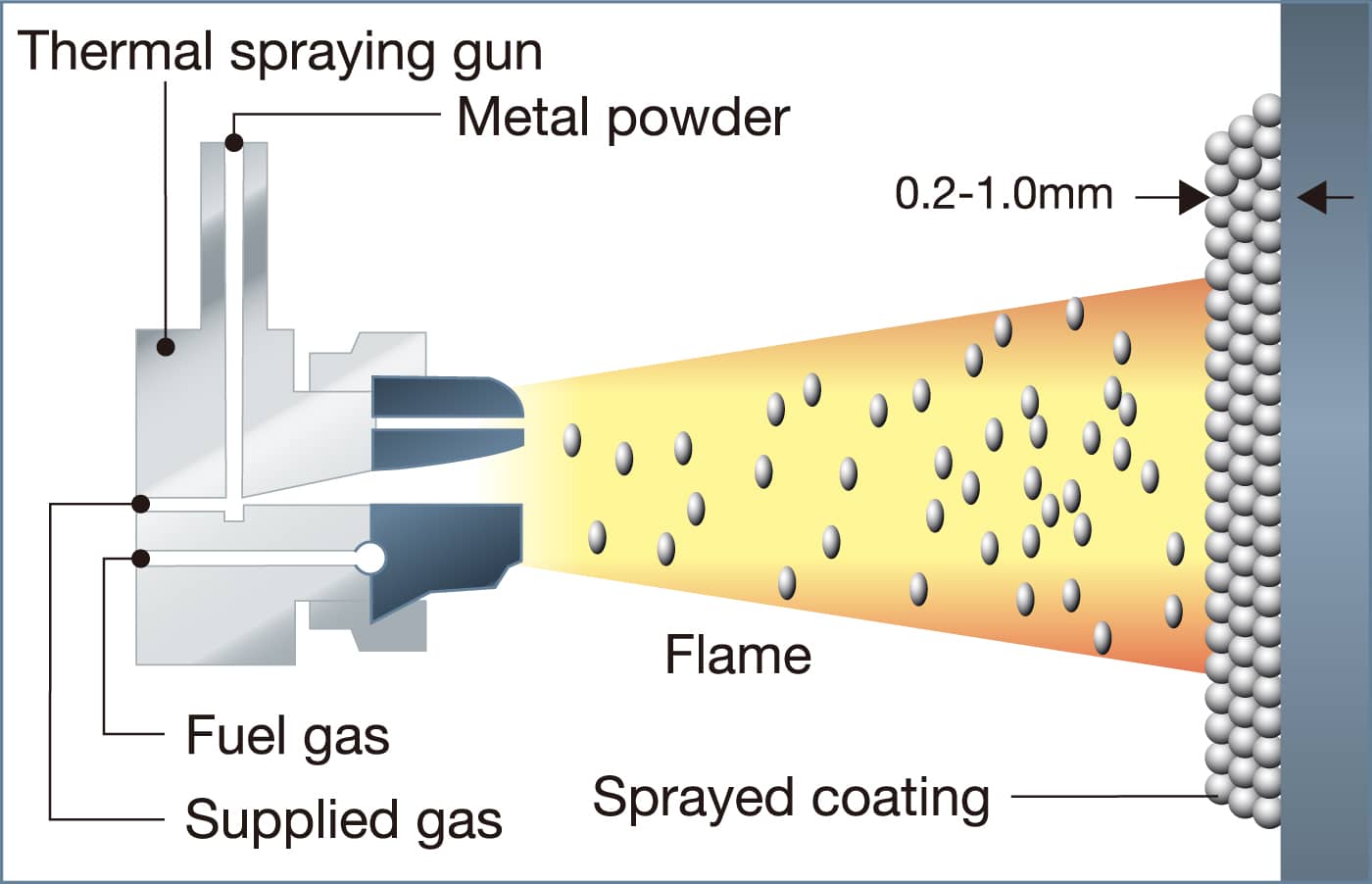

【 Thermal spraying 】

- Pipe and cylinder for oil drilling

- Mill roll

【 Brazing 】

- Metal honeycomb

- EGR coller

- Heat exchanger

Main applications

| Target | Applications |

|---|---|

| Welding |

|

| Brazing |

|

Main powder products

| Material | Chemical Compositions (mass%) |

Hardness (HRC) |

Corresponding material type | |||||||||

| C | Si | Ni | Cr | Mo | W | Co | V | Fe | ||||

| Co-base | DAPKCW1 | 2.5 | 1.1 | 1 | 30 | - | 12 | Bal. | - | - | 53 | JIS CoCrW 50 30 12 St-#1 |

| DAPKCW2 | 1.2 | 1.1 | 1 | 30 | - | 4 | Bal. | - | - | 43 | JIS CoCrW 60 28 4 St-#6 | |

| DAPKCW3 | 1.7 | 1.1 | 1 | 30 | - | 8 | Bal. | - | - | 47 | JIS CoCrW 53 30 8 St-#12 | |

| DAPKCM1 | 0.3 | 1.1 | 3 | 26 | 5.5 | - | Bal. | - | - | 30 | JIS CoCrMo 60 27 5 St-#21 | |

| DAPKCN1 | 1.8 | 1.1 | 22 | 26 | - | 12 | Bal. | - | - | 41 | JIS CoCrNiW 40 25 22 10 St-#32 | |

| DAPSKMC400 | - | 2.5 | - | 8 | 28.0 | - | Bal. | - | - | 53 | T-400 | |

| DAPKV10 | 2.1 | 0.9 | 3 | 22 | 4.3 | - | Bal. | 9 | ≤5 | 50 | Developed steel by Daido | |

| DAPKV15 | 3.1 | 0.9 | 3 | 22 | 4.3 | - | Bal. | 13 | ≤6 | 53 | Developed steel by Daido | |

| DAPCCM29 | - | - | - | 29 | 6.0 | - | Bal. | - | - | - | ||

| Ni-base | DAPR625 | - | - | Bal. | 21 | 9.0 | - | - | - | - | 22 | DSALOY625 |

| DAPBNi-5 | - | 10.0 | Bal. | 19 | - | - | - | - | - | - | BNi-5 | |

| Fe-base | DAPFCN1 | 2.3 | 1.1 | 11 | 24 | 5.5 | - | - | - | Bal. | 46 | Developed steel by Daido |

※We can also produce metal powder of chemical compositions not listed in this table.Please contact us.

Typical particle size

| Mesh | µm |

|---|---|

| -#60 / +#250 | -250 / +63 |

| -#80 / +#350 | -180 / +45 |

| -#150 / +#350 | -100 / +45 |

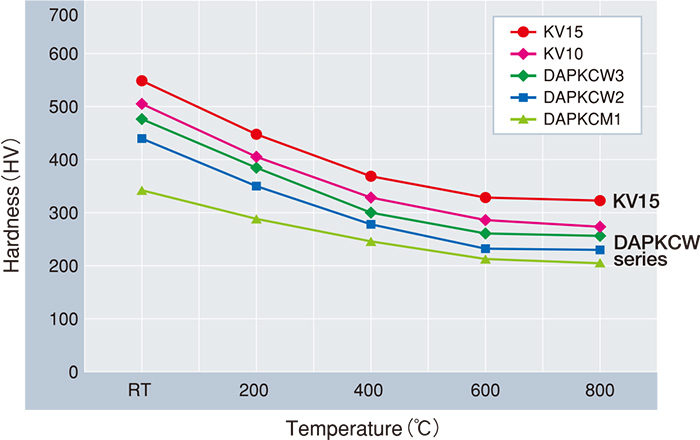

Hardness of DAPKV at elevated temp.

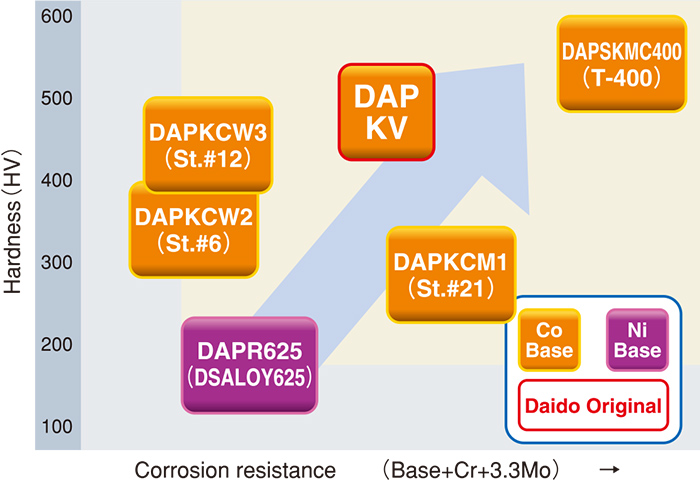

Concept of original powder DAPKV

※According to welding process, property and chemical composition of welded parts are possibly different from those of powders