DAPTM-AM Series - Metal Powders for 3D Printing -

- Metal powders for 3D printing by Directed Energy Deposition

High Thermal Conductivity Powders for Molds DAPTM-AM HTC45

DAPTM-AM HTC45 is SKD61-based powder adjusted to a composition suitable for additive manufacturing of die-casting molds.

Hardness suitable for die-casting molds can be obtained by just directed energy deposition.

Feature

- DAPTM-AM HTC45 has spherical shape, low oxygen content and high flowability produced by gas atomization.

- DAPTM-AM HTC45 is cobalt free material, the same as SKD61.

- The hardness suitable for die-casting molds of 45-48HRC can be obtained by directed energy deposition, and no post-heat treatment is required.

- The high thermal conductivity of the overlay portion enhances the cooling effect of the mold.

In addition, thermal stress can be reduced and heat checking can be effectively suppressed.

Major application

- Repair of die casting molds

Typical Chemical composition and hadness range

| DAPTM-AM Series | Equivalent steel grade | Hardness range after directed energy deposition (HRC) | Typical chemical composition(mass%) | ||||

| C | Si | Cr | Mo | V | |||

|

|

SKD61 type Die Steel |

45~50 | 0.23 | 0.1 | 5 | 1.2 | 0.4 |

Particle size

| Particle size (µm) |

| -150/+53 |

Characteristics

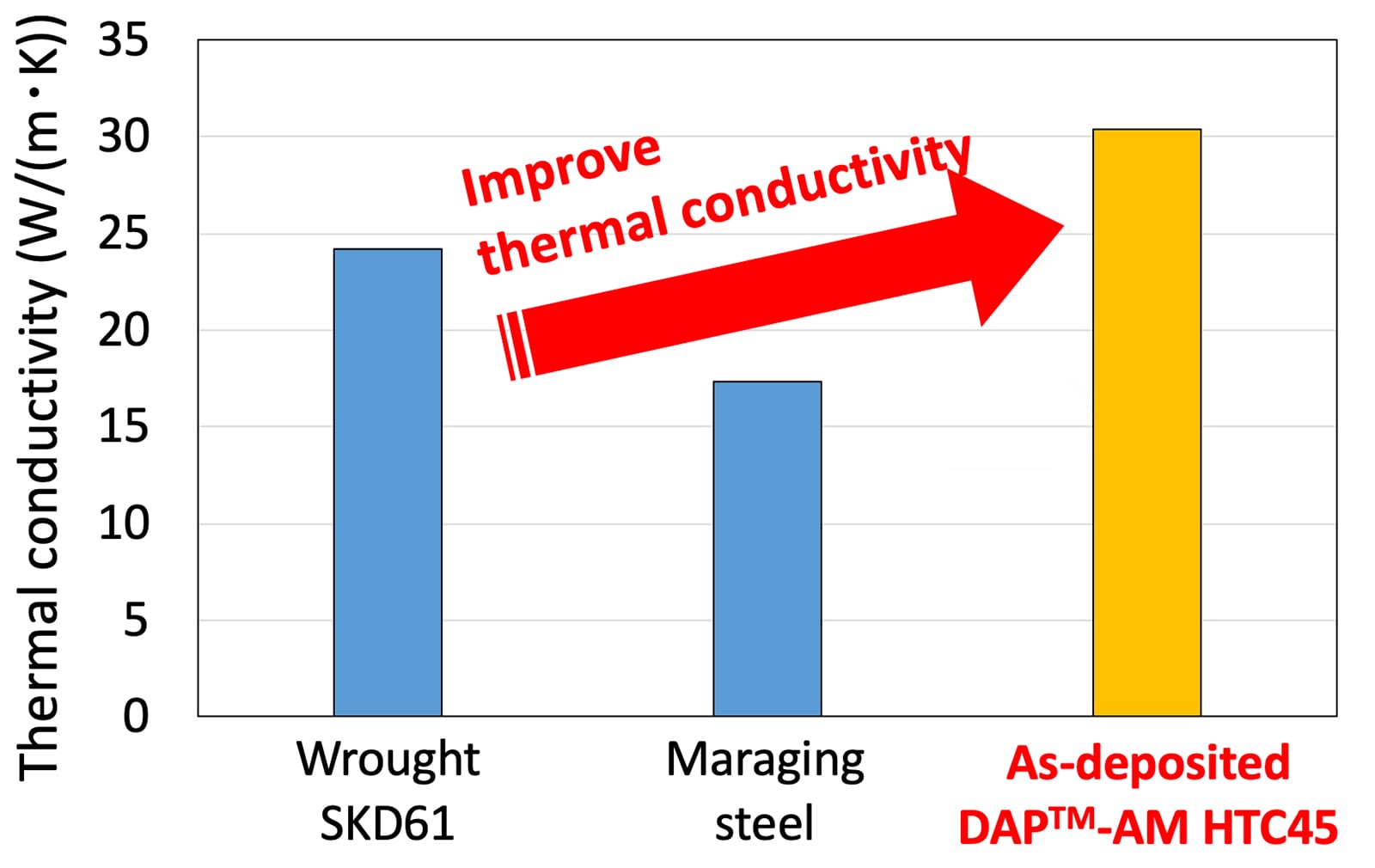

The thermal conductivity of DAPTM-AM HTC45 is about twice than that of maraging steel and about 1.5 times than that of SKD61 steel.

Fig.1 Thermal conductivity at RT

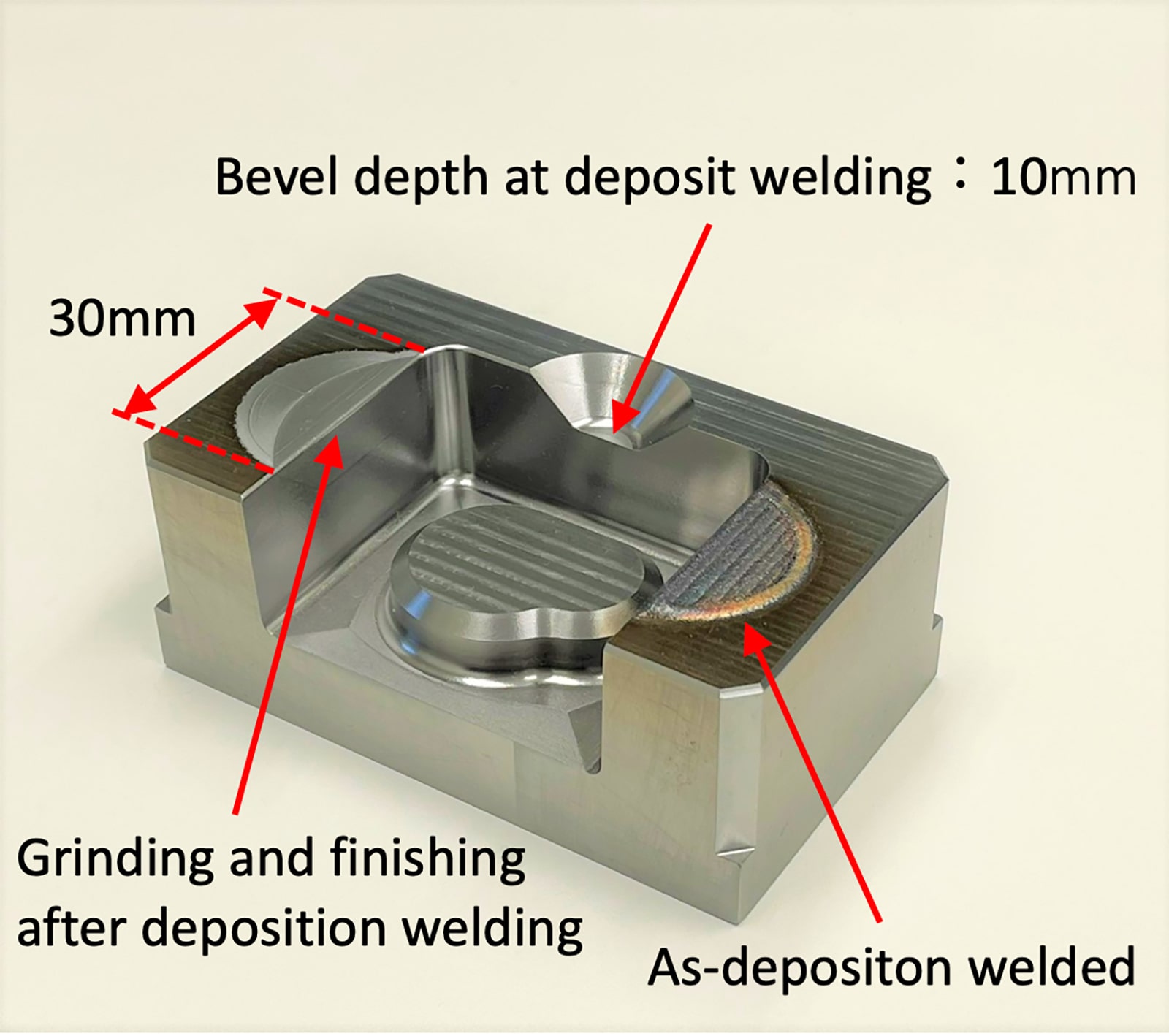

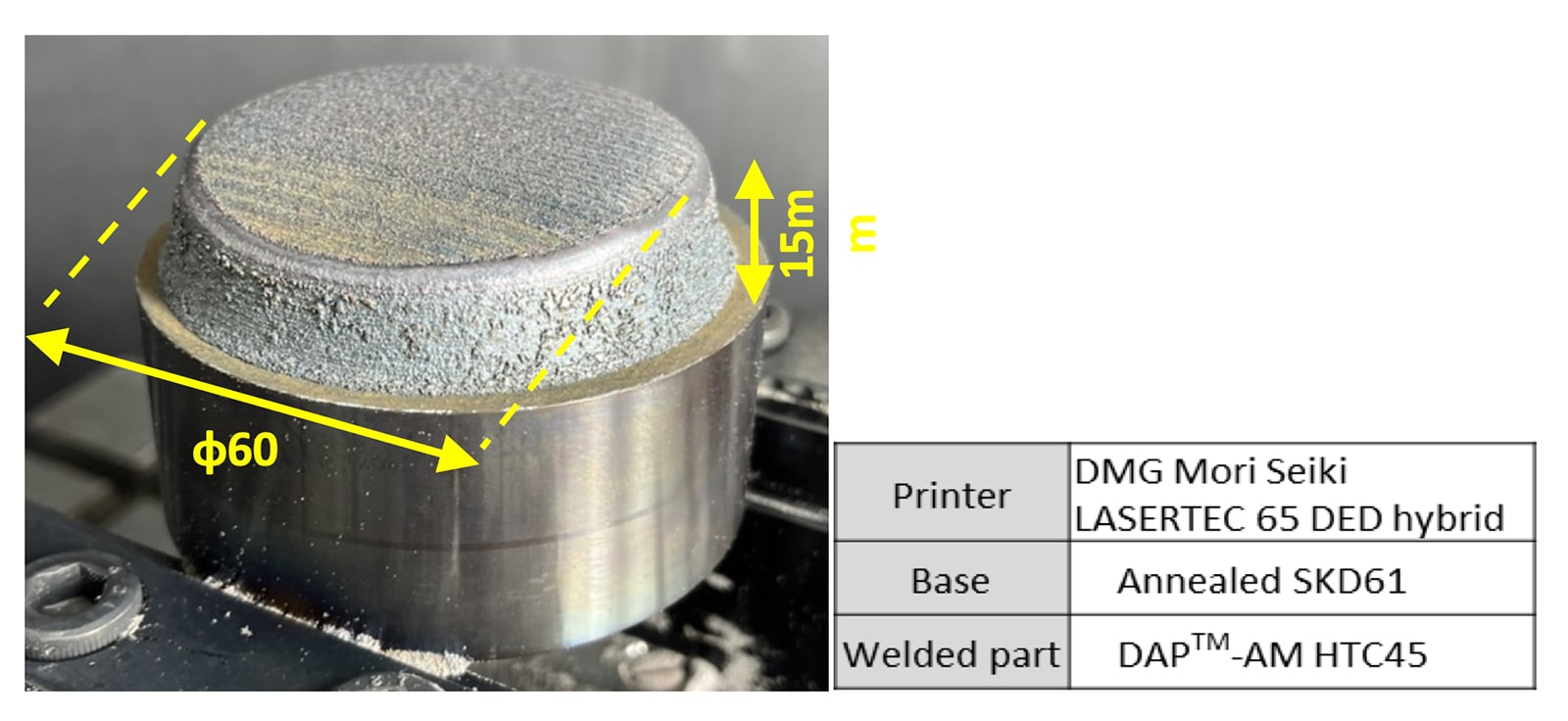

Fig.2 Overview of deosited sample

(3D-printed by FUJI COOPORATION)

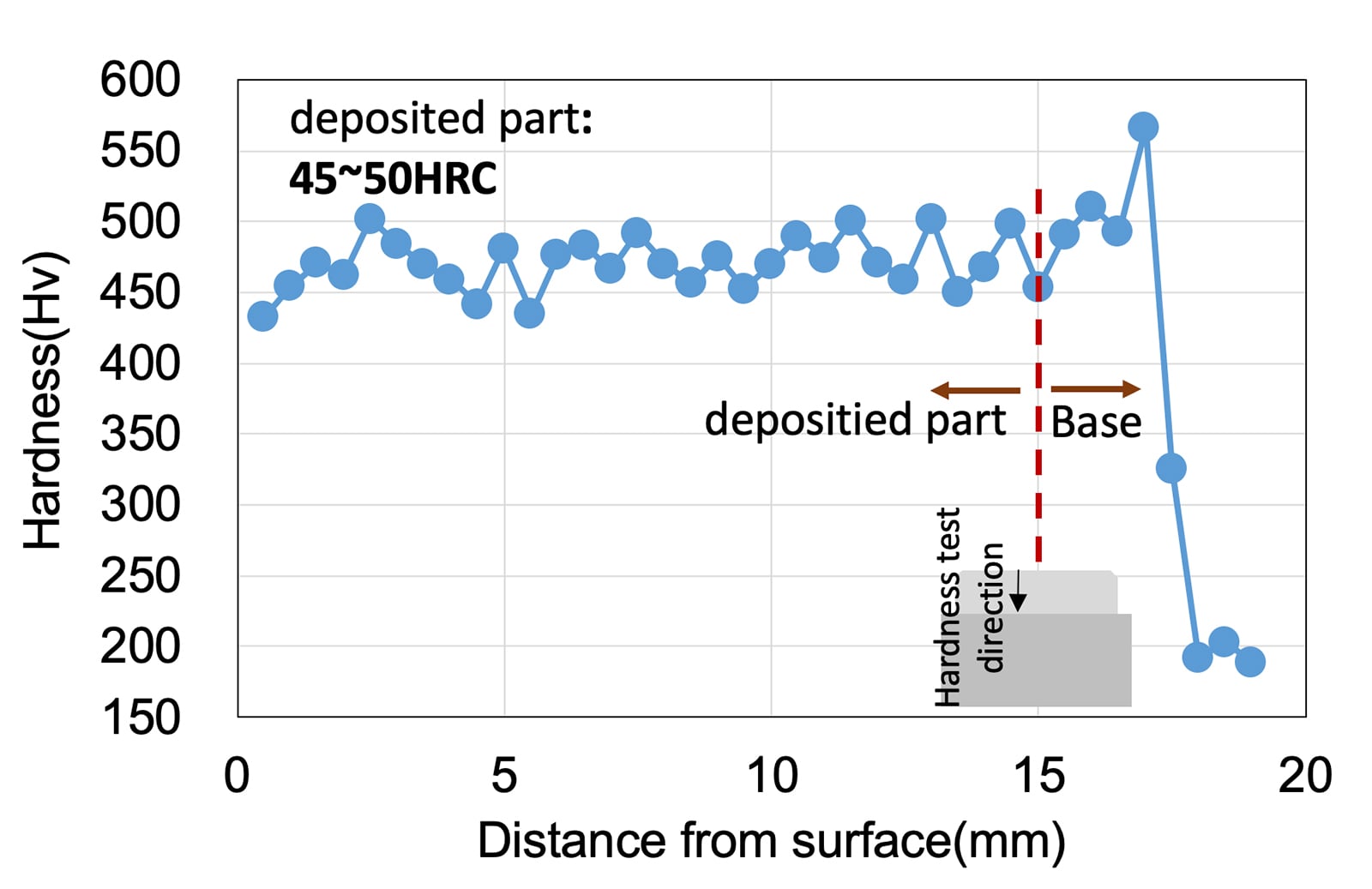

Fig.3 Hardness distribution of the deposited part

for As-3D printed DAPTM-AM HTC 45

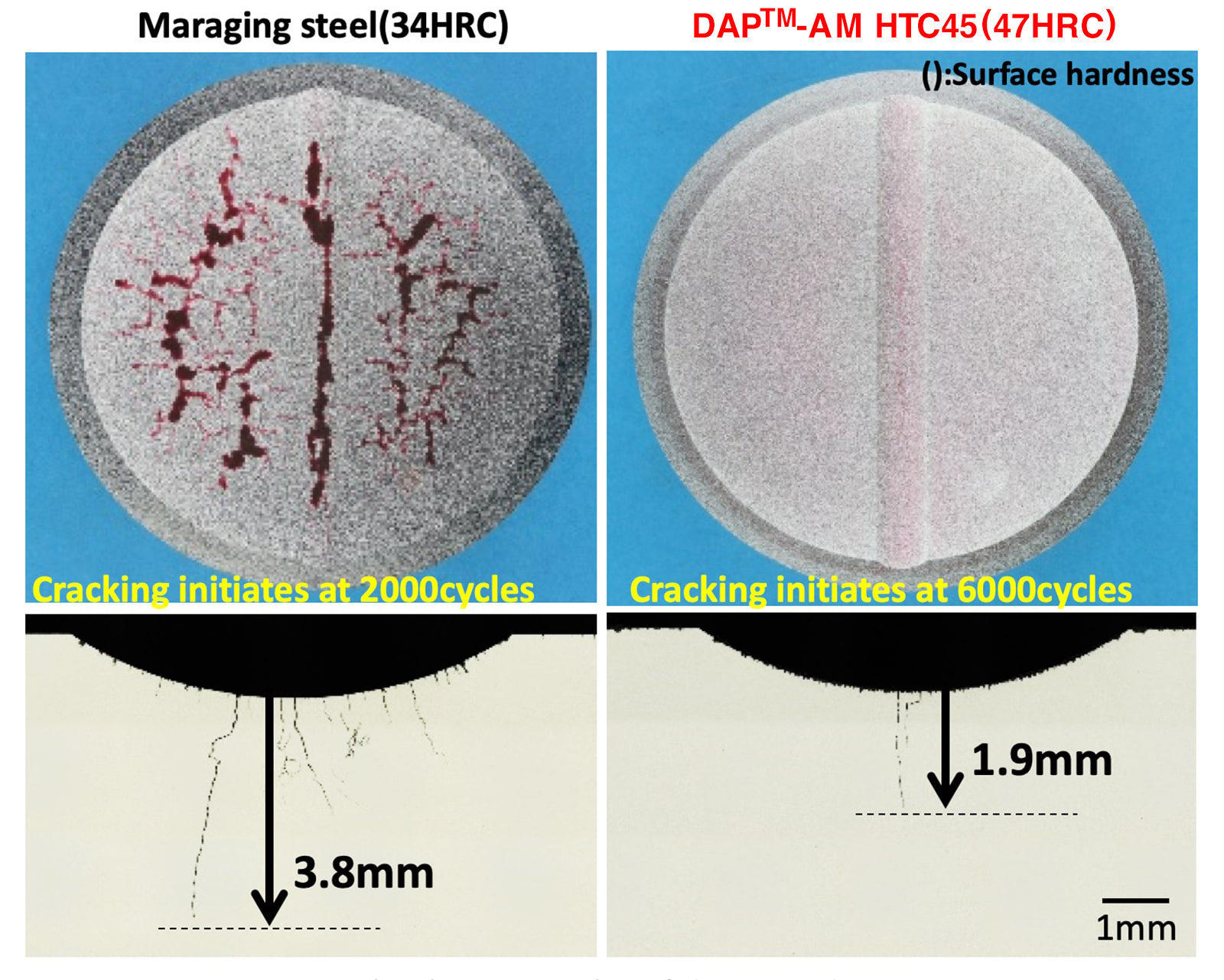

DAPTM-AM HTC 45 has a higher hardness than maraging steels after overlay weling.

Its high thermal conductivity suppresses heat checking.

Fig.4 Heat check test results of deposited specimens

(After 6000cycles, Notch shape:R=6mm, depth:1mm)

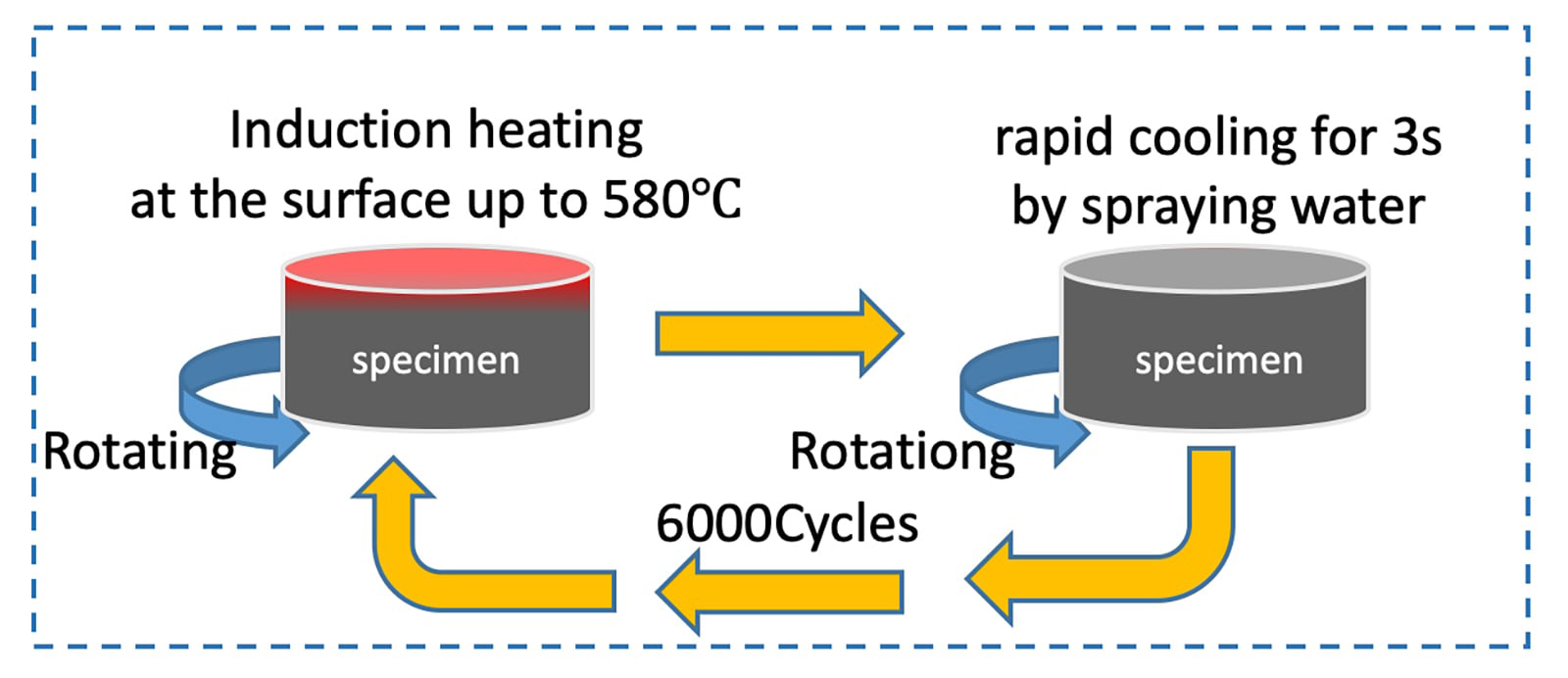

Fig.5 Shematic diagram of heat check test

Deposition welded sample

Technical data

Disclaimer and copyright

The figures in this document are typical values based on the results of our tests and there is no guarantee that the figures presented will be achieved when the products are used.

The information in this document is subject to change without notice.

Please contact us for the latest information.Any unauthorized distribution or reproduction of the content of this document is prohibited.

DAP and HTC are trademarks or registered trademarks of Daido Steel Co., Ltd.