AMDAPTM Series - Metal Powders for 3D Printing -

- Metal powders for 3D printing by SLM

Stainless steel powder for 3D-printing large plastic molds AMDAPTM LTX420

AMDAPTM LTX420 have been developed by adjusting chemical composition of metal powder suitable for additive manufacturing for large plastic molds exceeding 150mm square by SLM.

Characteristics

- Powders are produced by gas atomization and have high flowability.

- SUS420J2 (AISI 420M) based powder, widely used for plastic molds, optimized for 3D printers.

- Large-sized products can be 3D-printed with preheating at 120℃ without special treatment.

- Quenching and tempering hardness are equivalent to SUS420J2 and 53HRC can be obtained.

- Corrosion resistance is equivalent to SUS420J2.

- As pinholes possible to occur due to 3D-printing process, caution is necessary when it uses for high-mirror finish applications.

Major applications

Plastic molds requiring corrosion resistance and wear resistance

Typical chemical composition and hardness range

| Equivalent steel grade | Typical chemical composition(mass%) | Hardness in use(HRC) | ||||

| C | Ni | Cr | V | |||

| AMDAPTM LTX420 | JIS SUS420J2 type stainless steel |

0.27 | 1.5 | 13 | 0.1 | Tempering at 200℃:53HRC Annealing at 700℃:32HRC |

Particle size

| Particle size (µm) |

| -53/+25 |

Mold manufacturing process

Fig. 1 Mold manufacturing process of AMDAPTM LTX420.

| Part | Laser power(W) | Laser spot diameter(μm) | Scanning speed(mm/s) | Hatching distance(mm) | Layer thickness(μm) |

| Inside | 375 | 180 | 750 | 0.13 | 50 |

| Contour | 150 | 100 | 350 | ― | 50 |

*1The data shown in Table 1 are 3D printing process parameters for GE Additive’s Concept Laser M2 machine.

When using other equipment, please refer to the table for optimizing conditions.

Please feel free to ask our Metal Powder Department about the process parameters.

Heat treatment properties

Hardness equivalent to annealed SUS420J2 steel can be obtained by annealing twice at 700℃.

Fig.2 Relationship between annealing temperature and hardness after 3D-printing.

Quenching and tempering properties are equivalent to SUS420J2 type steel.

Fig.3 Relationship between tempering temperature and hardness.

Mechanical properties

AMDAPTM LTX420 has slightly lower proof stress than wrought SUS420J2 type steel.

Charpy impact value of AMDAPTM LTX420 shows higher value than that of wrought SUS420J2 type steel.

Fig. 4 Comparison of mechanical properties.

Corrosion resistance

Corrosion resistance is equivalent to SUS420J2 series steel.

Fig.5 Comparison of corrosion resistance by wet test.

(Set temperature:50℃, Humidity:90%, Holding time:48h)

Thermal conductivity

Thermal conductivity is equivalent to SUS420J2 type steel.

Fig.6 Comparison of thermal conductivity of low-temperature tempered materials.

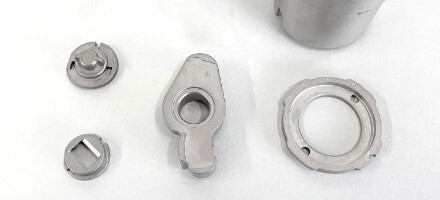

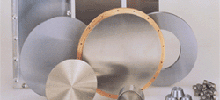

3D-printed sample

Fig.7 Example of 3D-printed sample.

(baseplate temperature 120℃)

Disclaimer and copyright

The figures in this document are typical values based on the results of our tests and there is no guaranteethat the figures presented will be achieved when the products are used.

The information in this document is subject to change without notice.

Please contact us for the latest information.Any unauthorized distribution or reproduction of the content of this document is prohibited.

AMDAP and LTX are trademarks or registered trademarks of Daido Steel Co., Ltd.