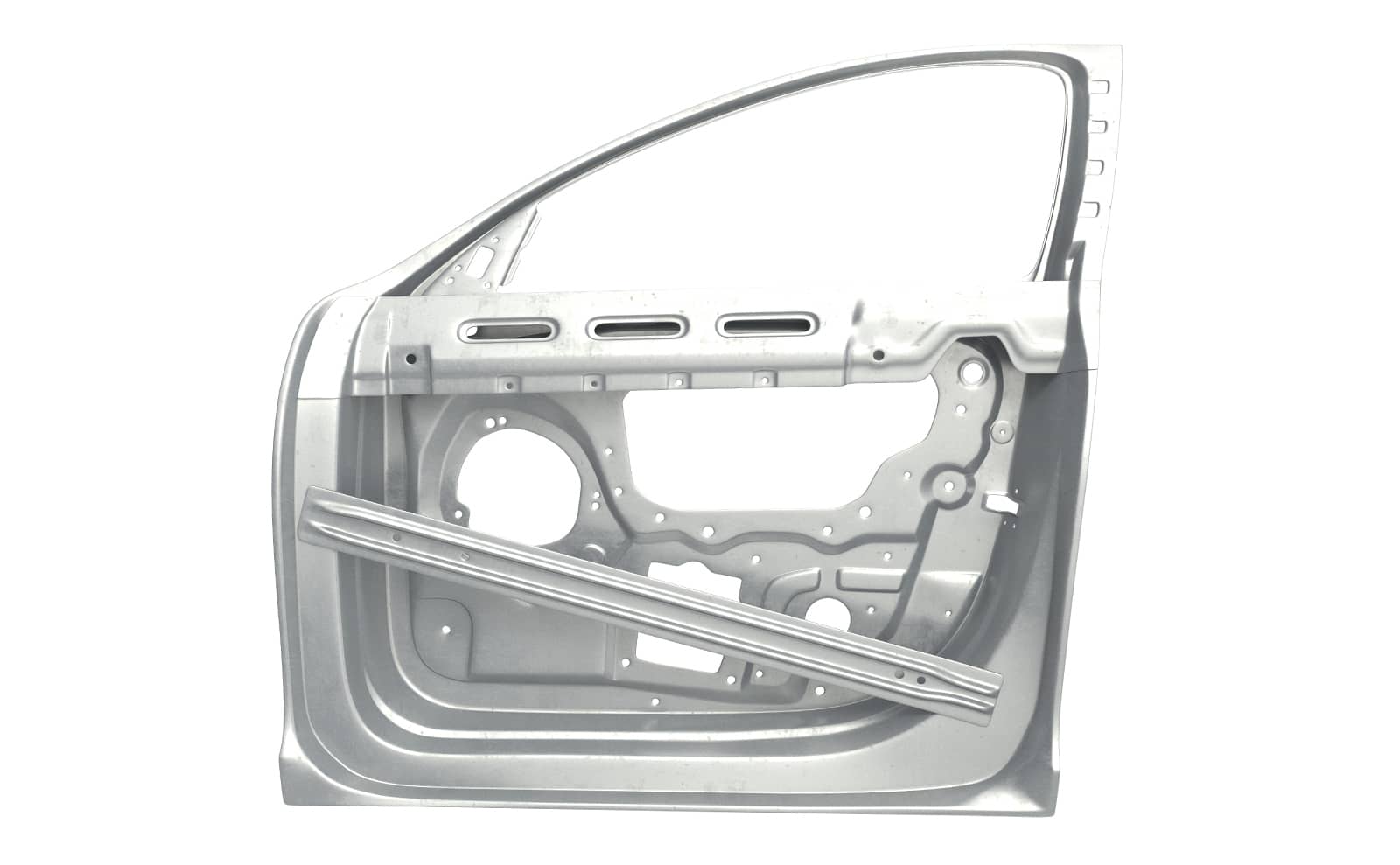

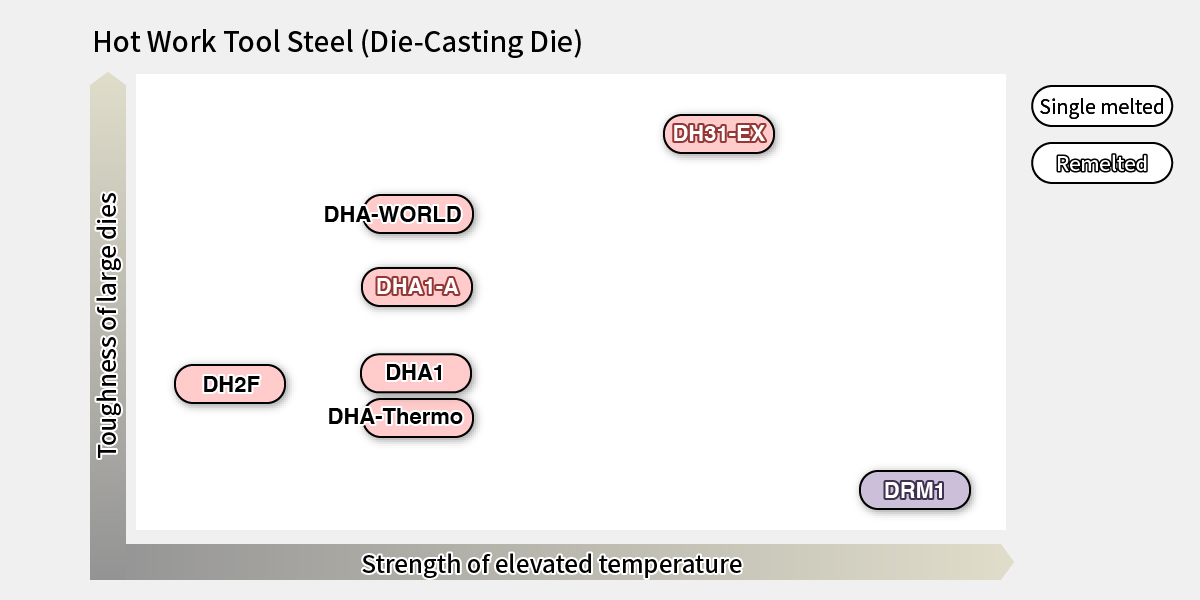

Hot Work Tool Steel (Die-Casting Die)

Daido Steel's tool steels lineup for die casting includes H13, matrix-high-speed steel, and original steel grades with excellent thermal conductivity and hardenability for large products.

Our products contribute to the prevention of heat checking, soldering, erosion and other issues that may happen in Al, Zn and Mg die-casting. Surface treatment such as nitriding or PVD coating is also possible.

Conceptual diagram

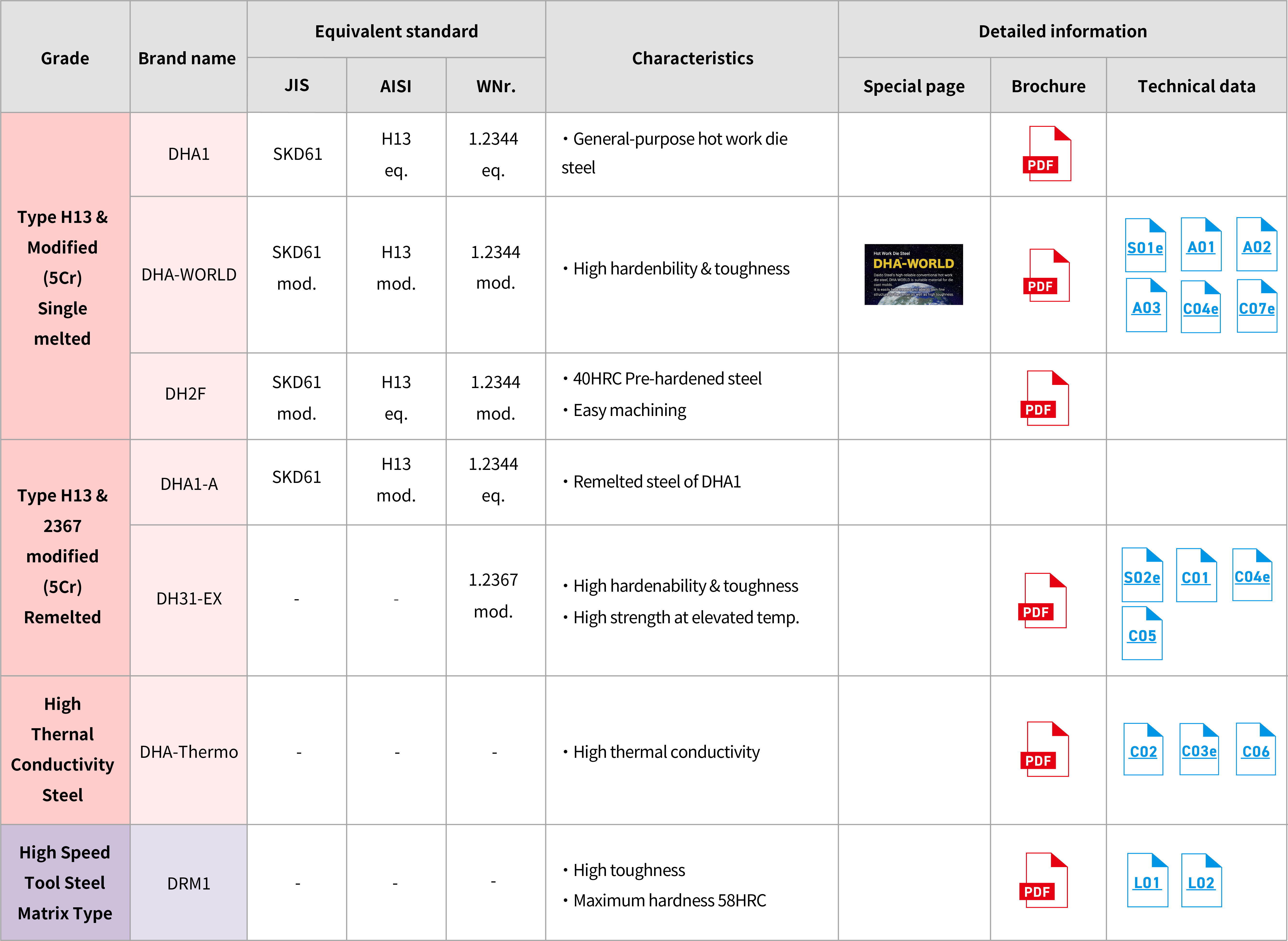

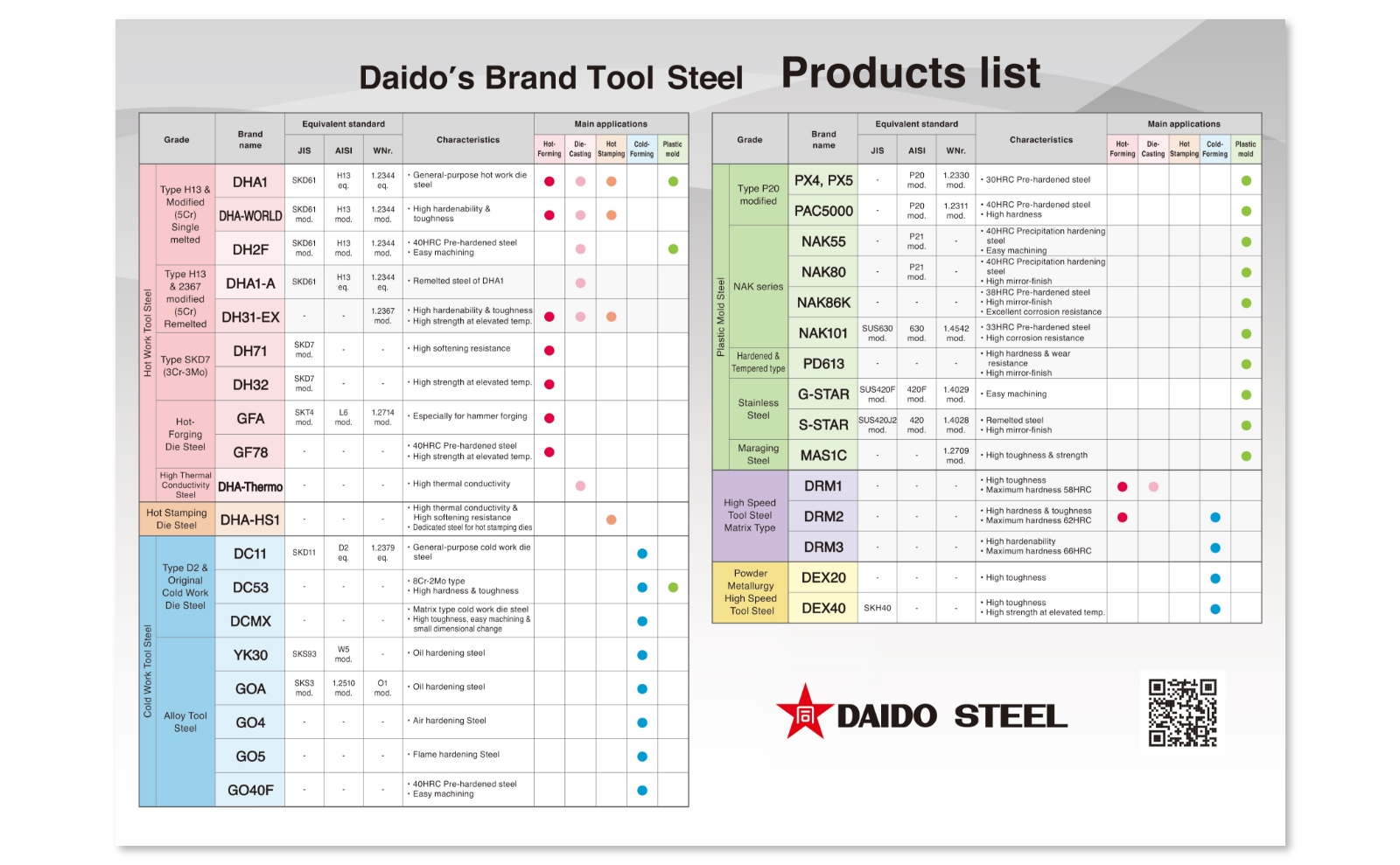

Products list

For the latest physical property data, please see "Physical Properties“.

Values listed in the brochure may differ.

Tool Steel

Tool Steel

Technical Data

| No. | Title | Publication / Source | Volume & page | Read the document |

| S01e |

Document with comments "DHA-WORLD" (No. SD2002) |

- | - | Open PDF file |

| S02e |

Document with comments "DH31-EX" (No. SD2001) |

- | - | Open PDF file |

| A01 | 熱間工具鋼の被削性におよぼすSi量の影響 | 大同特殊鋼技報「電気製鋼」 | 2000年 71巻 2号 p.119-129 | Go to J-STAGE site |

| (A01e) |

Effect of Si Content on the Machinability of Hot Working Die Steels (No. SD2005) |

Source: DENKI-SEIKO (Electric Furnace Steel) |

2000, Vol. 71, No. 2, p. 119-129 | Open PDF file |

| A02 | 熱間工具鋼の被削性におよぼすSiおよび硬さの影響 | 大同特殊鋼技報「電気製鋼」 | 2003年 74巻 2号 p.83-92 | Go to J-STAGE site |

| A03 | 高信頼性汎用熱間ダイス鋼 “DHA-WORLD” | 大同特殊鋼技報「電気製鋼」 | 2010年 81巻 1号 p.47-52 | Go to DENKI-SEIKO page |

| C01 | ダイカスト金型のヒートチェックに及ぼす硬さと合金元素 “モリブデン、シリコン” の影響 | 大同特殊鋼技報「電気製鋼」 | 2010年 81巻 1号 p.25-31 | Go to DENKI-SEIKO page |

| C02 |

ダイカスト金型用の高熱伝導率工具鋼 “DHA-Thermo” |

大同特殊鋼技報「電気製鋼」 | 2010年 81巻 1号 p.41-46 | Go to DENKI-SEIKO page |

| C03e |

High Thermal Conductivity Steel and its Application to Die Casting Tools (No. SD2103) |

Source: NADCA Die Casting Congress & Exposition |

2012, Transaction No. T12-071 | Open PDF file |

| C04e |

Development and Applications of High Hardenability Special Quality Die Casting Mold Steels (No. SD2104) |

Source: NADCA Die Casting Congress & Tabletop |

2013, Transaction No. T13-052 | Open PDF file |

| C05 | ダイカスト金型用鋼の衝撃値と耐ヒートチェック性 | 大同特殊鋼技報「電気製鋼」 | 2017年 88巻 2号 p.101-106 | Go to DENKI-SEIKO page |

| C06 | 分流子の熱伝導率がその温度とビスケット部の凝固組織におよぼす影響 | 大同特殊鋼技報「電気製鋼」 | 2020年 91巻 2号 p.91-96 | Go to DENKI-SEIKO page |

| C07e |

Gross crack mechanism analysis for die-casting die (No. SD2102) |

Source: KATA-GIJYUTSU (Die and Mould Technology) |

2020, Vol.35, No.12, p.42-43 | Open PDF file |

| L01 | 高硬度・高靭性マトリックスハイスDRM鋼の開発 | 大同特殊鋼技報「電気製鋼」 | 2005年 76巻 4号 p.279-286 | Go to J-STAGE site |

| (L01e) |

The Development of High Hardness and Toughness Matrix Type High Speed Tool Steels “DRM” (No. SD2108) |

Source: DENKI-SEIKO (Electric Furnace Steel) |

2005, Vol. 76, No. 4, p. 279-286 | Open PDF file |

| L02 | 金型用マトリックスハイスDRM鋼の実用事例 | 大同特殊鋼技報「電気製鋼」 | 2007年 78巻 4号 p.353-360 | Go to J-STAGE site |

Related Documents

| No. | Title | Publication / Source | Volume & page | Read the document |

| D01 | 熱間工具鋼の軟窒化後窒素濃度分布に及ぼす合金元素の影響 | 大同特殊鋼技報「電気製鋼」 | 2007年 78巻 4号 p.307-314 | Go to J-STAGE site |

| D02 | 熱間ダイス鋼における軟窒化拡散層のTEM組織観察 | 大同特殊鋼技報「電気製鋼」 | 2007年 78巻 4号 p.315-322 | Go to J-STAGE site |

| D03 | 湯流れ解析によるダイカスト金型のヒートチェック予測 | 大同特殊鋼技報「電気製鋼」 | 2014年 85巻 1号 p.53-61 | Go to DENKI-SEIKO page |

| D04e |

New Surfacing Material “DHW” (No. SD2105) |

Source: NADCA Die Casting Congress & Tabletop |

2016, Transaction No. T16-042 | Open PDF file |

| D05 | 数値解析によるダイカストの離型抵抗予測 | 大同特殊鋼技報「電気製鋼」 | 2017年 88巻 1号 p.33-38 | Go to DENKI-SEIKO page |

| D06e |

Evaluation of Heat Checking of Molds through Flow and Solidification Simulation (No. SD2106) |

Source: NADCA Die Casting Congress & Exposition |

2018, Transaction No. T18-012 | Open PDF file |