What is Isotropic SmFeN Magnetic Powder and Compounds (Isotropic SmFeN Bonded Magnets)?

Isotropic Sm-Fe-N bonded magnets are composed of the magnetic powder and binder.

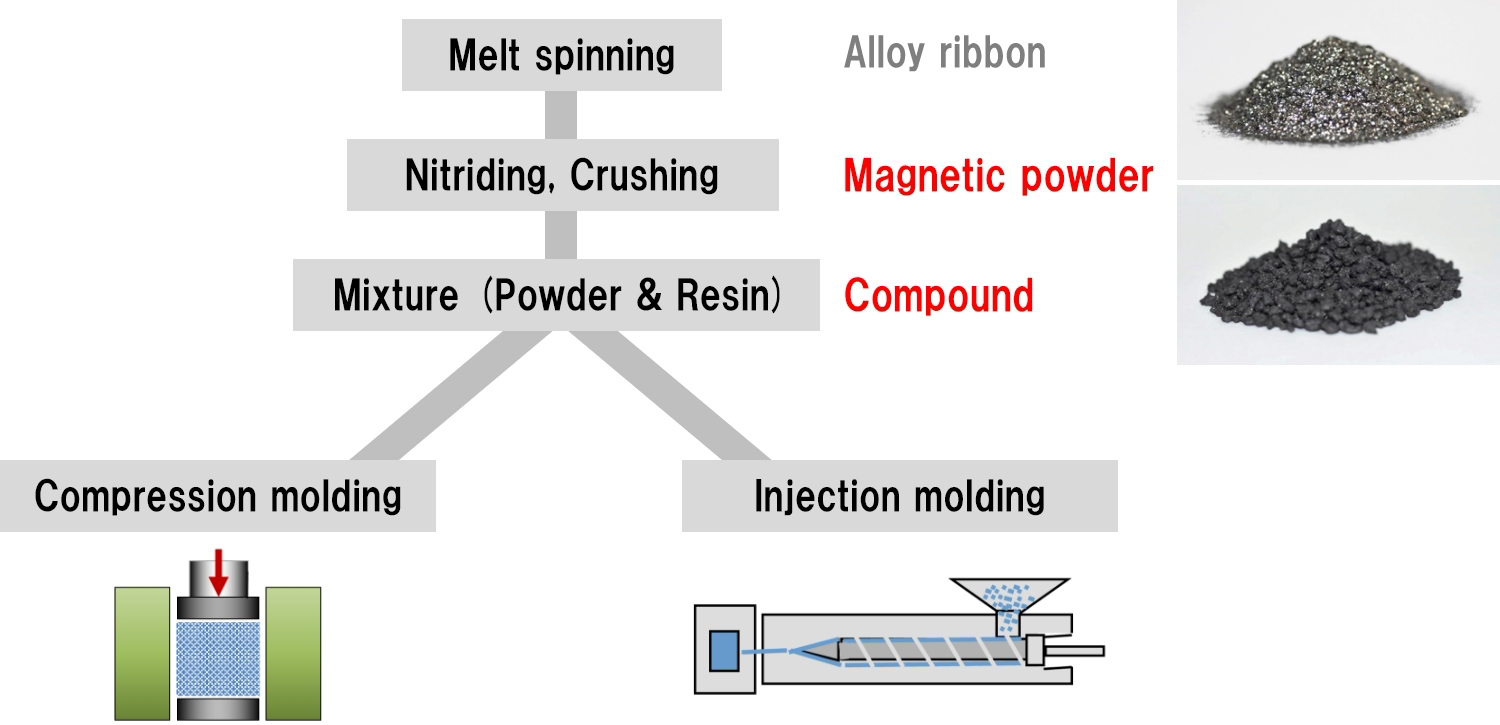

The magnetic powder which has polycrystalline, nanostructure is made by a rapid-quenching method, followed by nitriding.

Among isotropic bonded magnets, it has the world’s highest level of magnetic properties, and has excellent corrosion resistance and thermal stability.

We offer various forms such as magnetic powders, compounds, compression molded magnets, and injection molded magnets.

Characteristics of Isotropic SmFeN Magnetic Powder and Compounds (Isotropic SmFeN Bonded Magnets)

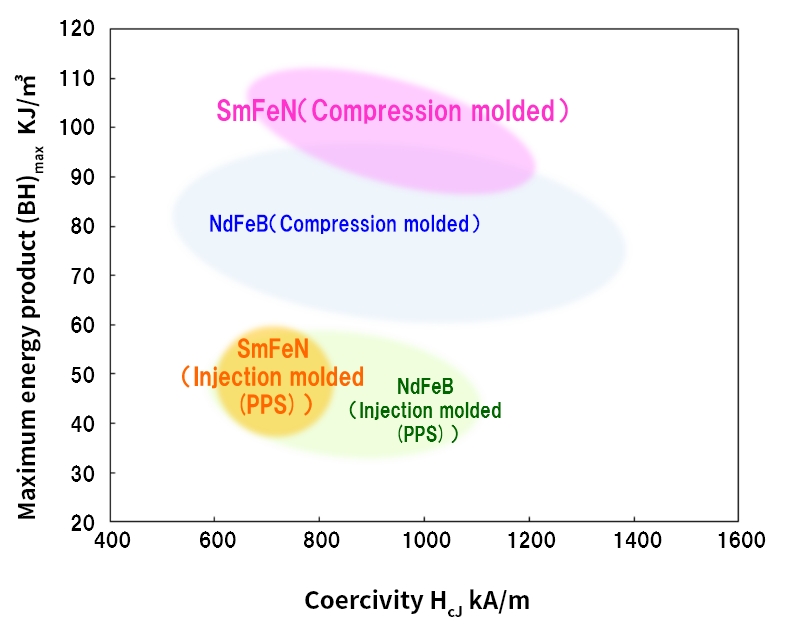

- Highest (BH)max among isotropic bonded magnets: ~112kJ/m3 (compression molded magnet)

- High corrosion resistance: Does not require coating in typical usage environment

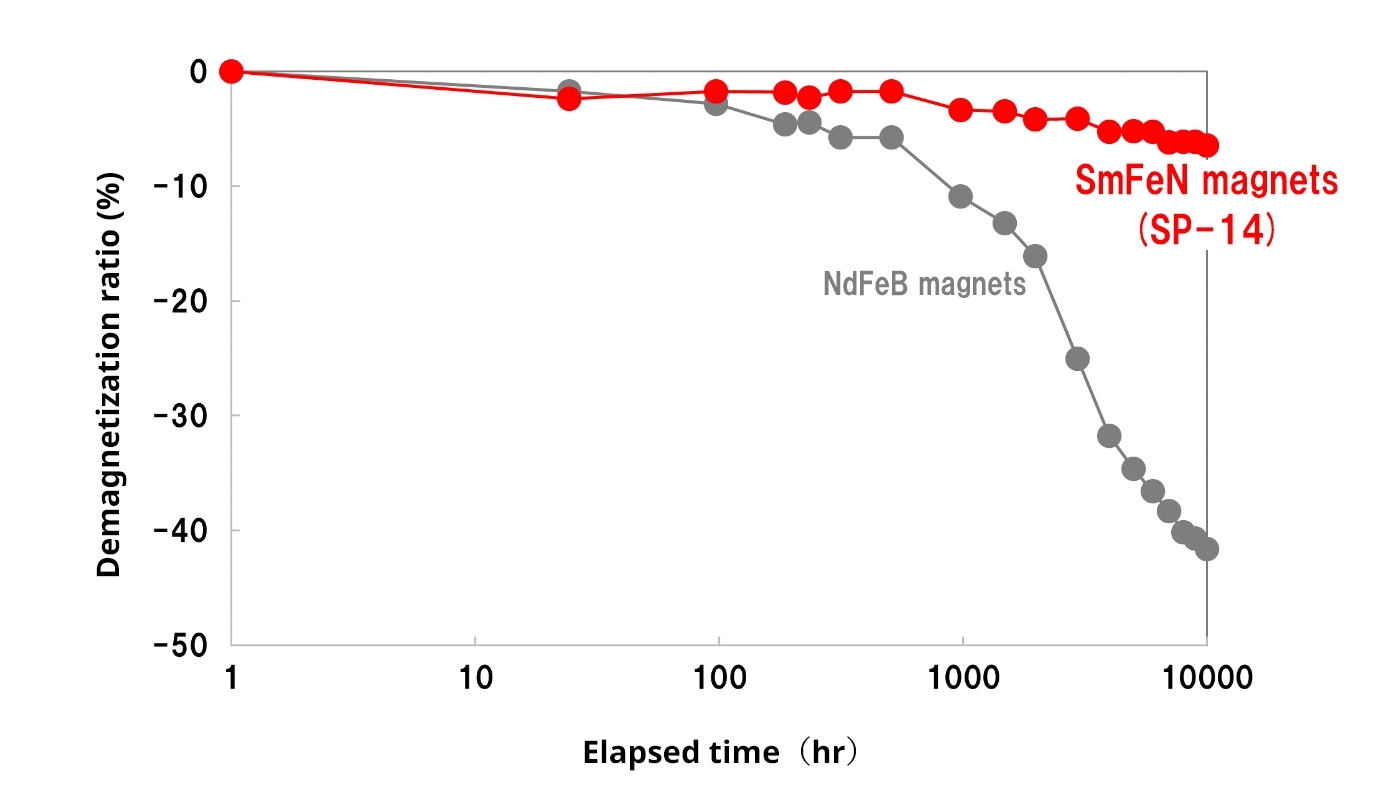

- High thermal stability:

Temperature coefficient of Br, α -0.06 ~ -0.07% /℃ (23 ~ 120℃) - Long-term thermal stability: Superior to Nd-Fe-B bonded magnets

- Injection molding:

Available with PPS (polyphenylene sulfide) which has excellent heat and chemical resistance. - Magnetizability: Requires higher magnetic fields than Nd-Fe-B bonded magnets

- Isotropic → Can be magnetized in any direction, realize flux paths with high permeance.

Isotropic Bonded Magnets by Daido Steel Group (Comparison of property Ranges)

Production process of isotropic SmFeN bonded magnets

Manufacturing and sales of isotropic SmFeN magnet powder, compound (powder with resin), and molded bonded magnets (compression molding and injection molding) by Daido Steel Group.

Bonded Magnets(Daido Electronics)

the website of Daido Electronics

Isotropic SmFeN magnetic powders

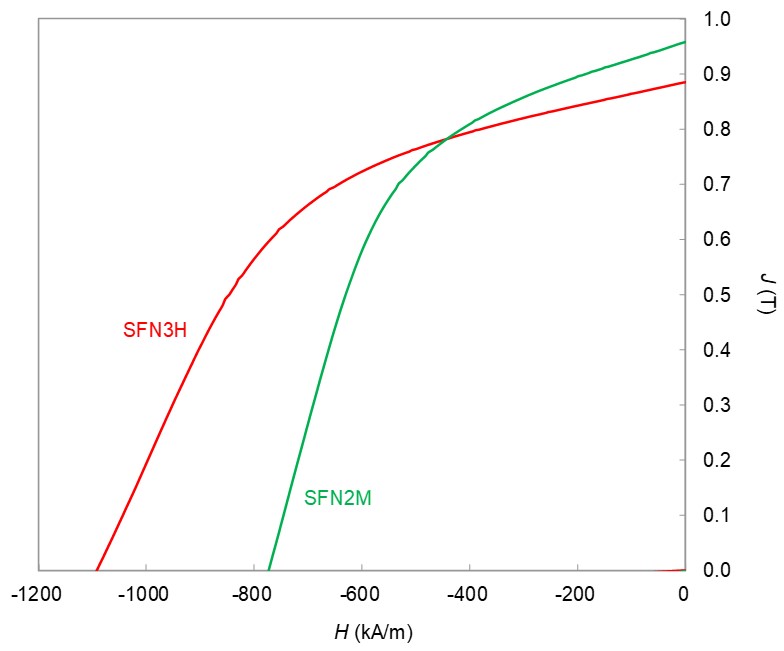

| unit | Isotropic SmFeN Magnetic Powder | ||

|---|---|---|---|

| Standard Type SFN2M |

High Coercivity Type SFN3H |

||

| Br | mT (kG) |

930 ~ 990 (9.3 ~ 9.9) |

860 ~ 920 (8.6 ~ 9.2) |

| HcJ | kA/m (kOe) |

614 ~ (7.8 ~ ) |

922 ~ (11.6 ~ ) |

| (BH)max | kJ/m3 (MGOe) |

136 ~ 157 (17.1 ~ 19.7) |

124 ~ 145 (15.6 ~ 18.2) |

※Notes※

- The magnetic properties of the powder are measured in the unmilled condition.

- Magnetic properties are measured after magnetization at 5 T.

- The data in this table are obtained from Daido's standard test pieces and do not represent guaranteed values.

- These values may vary depending on the magnet shape, dimensions, test conditions, and equipment. We recommend verifying the values using actual products.

- Guaranteed values can be established through consultation for specific shapes and sizes.

- The data are subject to change without notice.

Demagnetization Curves of Magnetic Powder(23℃)

Isotropic SmFeN compounds for compression molding

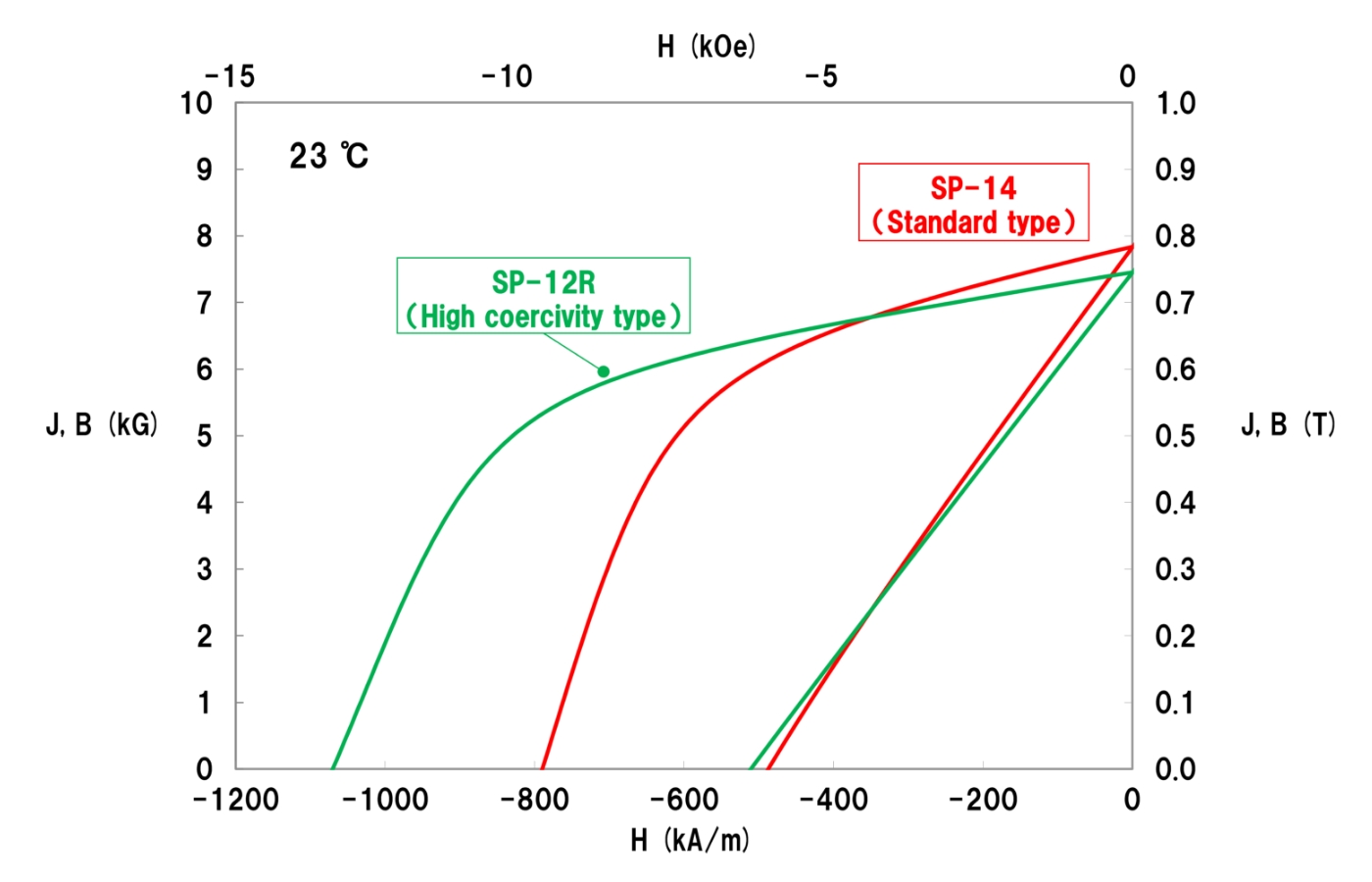

Compression molded isotropic SmFeN bonded magnets

Magnetic, physical, and mechanical properties

To meet the increasing demand for high heat resistance, we have newly introduced a high-coercivity type.

We will continue to expand our lineup to meet customers’ needs.

| unit | Isotropic SmFeN Magnet | ||

|---|---|---|---|

| Standard Type SP-14C(Compound) SP-14(Magnet) |

High Coercivity Type SP-12RC(Compound) SP-12R(Magnet) |

||

| Magnetic Powder Grade |

- | SFN2M | SFN3H |

| Br | mT (kG) |

750 ~ 820 (7.5 ~ 8.2) |

710 ~ 770 (7.1 ~ 7.7) |

| HcB | kA/m (kOe) |

450 ~ (5.7 ~ ) |

470 ~ (6.0 ~ ) |

| HcJ | kA/m (kOe) |

670 ~ (8.5 ~ ) |

980 ~ (12.4 ~ ) |

| (BH)max | kJ/m3 (MGOe) |

98 ~ 112 (12.4 ~ 14.0) |

86 ~ 99 (10.9 ~ 12.4) |

| μrec | - | 1.15 ~ 1.20 | 1.10 ~ 1.15 |

| α (23 ~ 120 ℃) |

%/℃ | -0.07 | -0.06 |

| β (23 ~ 120 ℃) |

%/℃ | -0.39 | -0.39 |

| Density | g/cm3 | 6.00 | 6.00 |

| Thermal Expansion Coefficient (20 ~ 100℃) |

10-5/℃ | 1.3 | 1.3 |

| Flexural Strength |

MPa (kgf/mm2) |

52 (5.3) |

52 (5.3) |

| Bending Elastic Modulus | MPa (kgf/mm2) |

10,800 (1,102) |

10,800 (1,102) |

| Ring Crushing Strength | MPa (kgf/mm2) |

54 (5.6) |

54 (5.6) |

※Notes※

- Magnetic properties are measured after magnetization at 5 T.

- The data in this table are obtained from Daido's standard test pieces and do not represent guaranteed values.

- These values may vary depending on the magnet shape, dimensions, test conditions, and equipment. We recommend verifying the values using actual products.

- Guaranteed values can be established through consultation for specific shapes and sizes.

- The data are subject to change without notice.

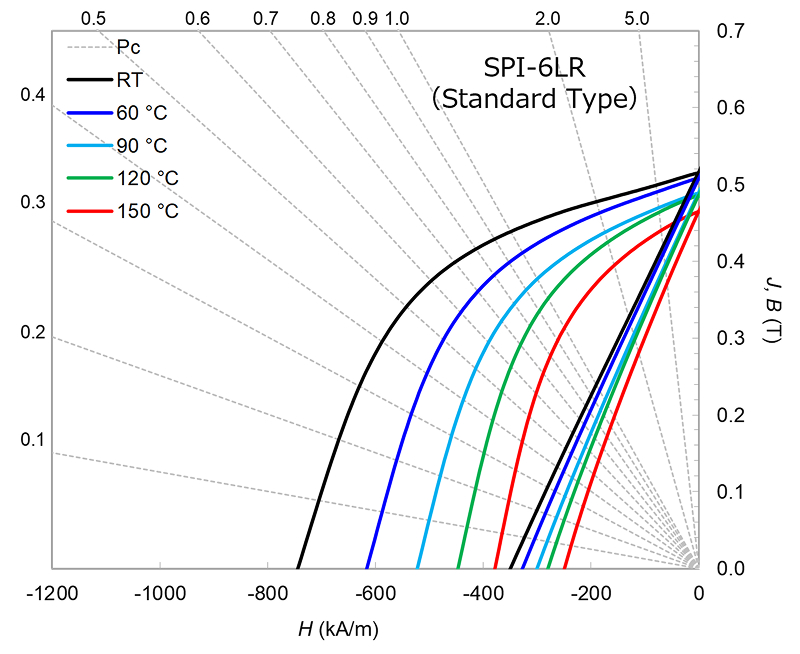

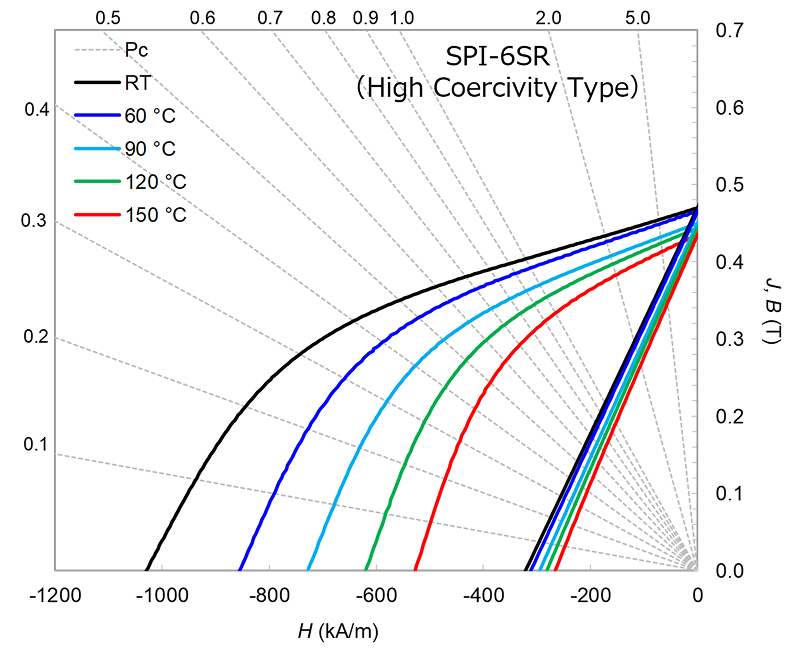

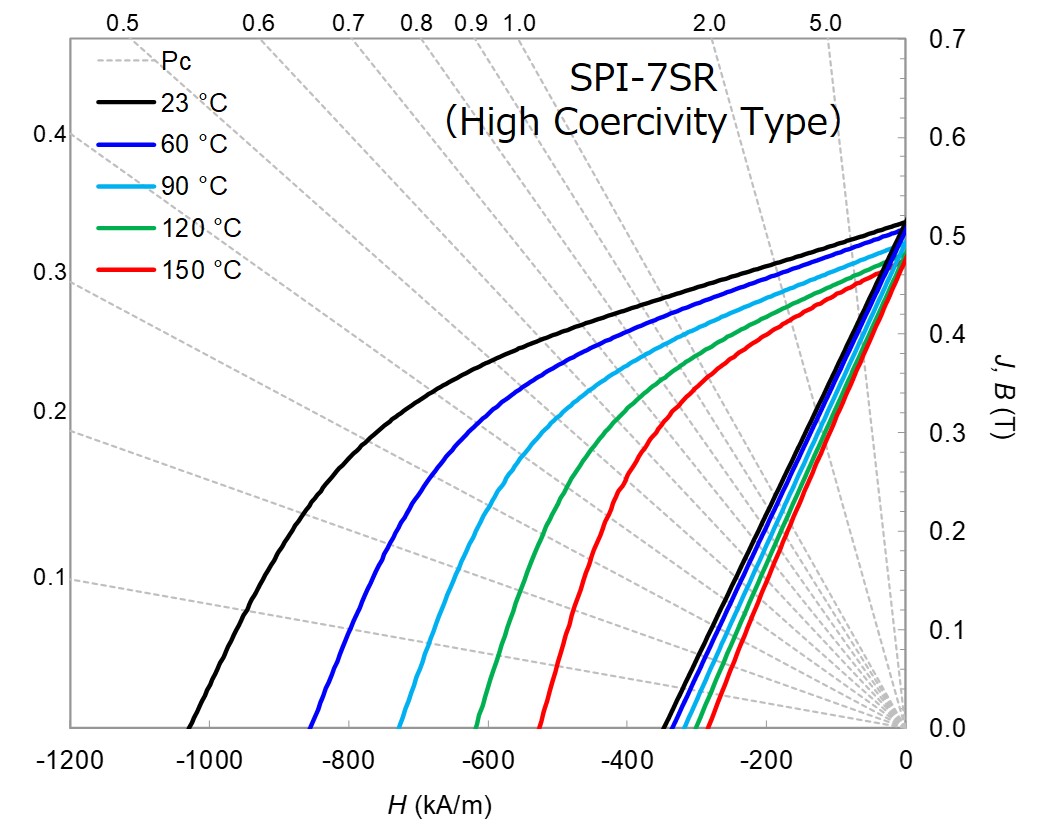

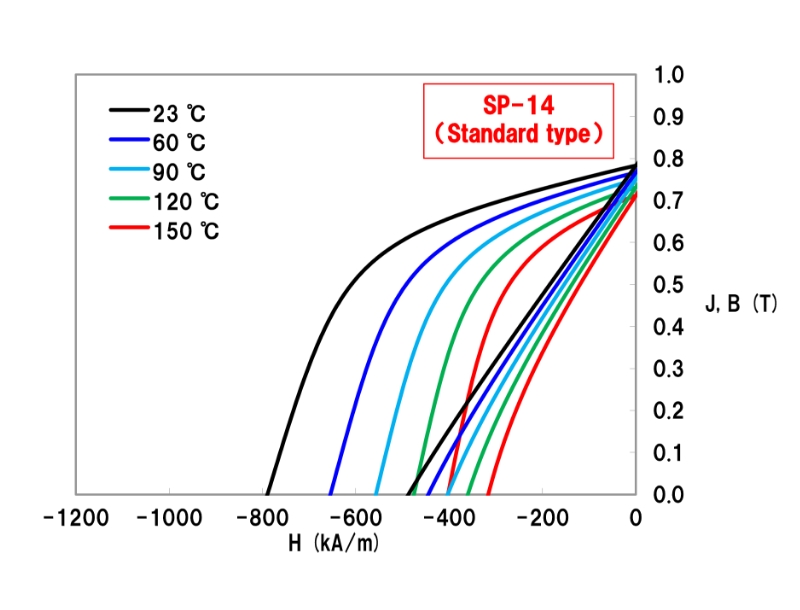

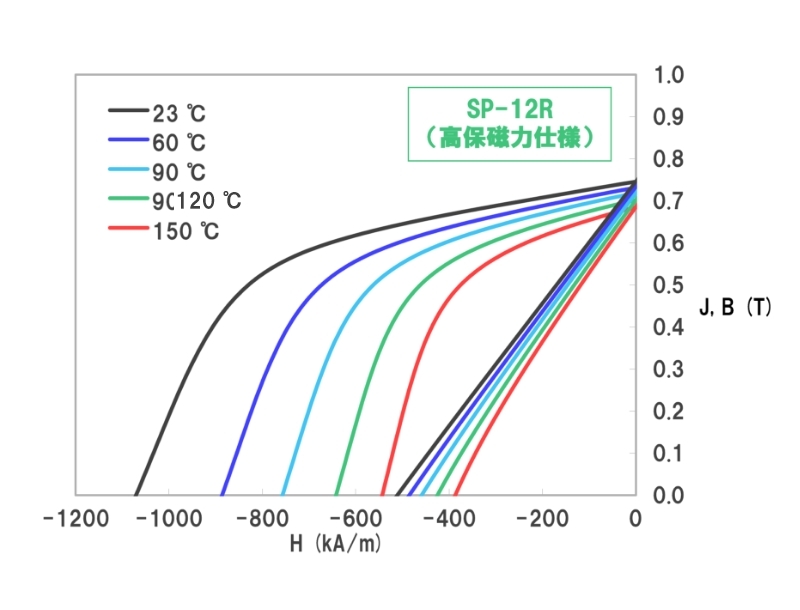

Demagnetization Curves of Compression-Molded Bonded Magnets at Elevated Temperatures

(23 ~ 150 ℃)

Corrosion resistance: Long-Term Corrosion Resistance (Uncoated)

Corrosion resistance: Long-Term Thermal Resistance (Uncoated)

Isotropic SmFeN Magnets: Injection Molding Compound and Bonded Magnets (PPS Grade)

Magnetic, physical, and mechanical properties

| unit | Isotropic SmFeN Magnet | ||||

|---|---|---|---|---|---|

| Standard Type SC-6LR(Compound) SPI-6LR(Magnet) |

Standard Type SC-7LR(Compound) SPI-7LR(Magnet) |

High Coercivity Type SC-6SR(Compound) SPI-6SR(Magnet) |

High Coercivity Type SC-7SR(Compound) SPI-7SR(Magnet) |

||

| Magnetic Powder Grade |

- | SFN2M | SFN2M | SFN3H | SFN3H |

| Resin | - | PPS | PPS | PPS | PPS |

| Br | mT (kG) |

480 ~ 560 (4.8 ~ 5.6) |

540 ~ 620 (5.4 ~ 6.2) |

430 ~ 510 (4.3 ~ 5.1) |

470 ~ 550 (4.7 ~ 5.5) |

| HcB | kA/m (kOe) |

302 ~ (3.8 ~ ) |

335 ~ (4.3 ~ ) |

287 ~ (3.7 ~ ) |

318 ~ (4.0 ~ ) |

| HcJ | kA/m (kOe) |

572 ~ (7.2 ~ ) |

572 ~ (7.2 ~ ) |

851 ~ (10.7 ~ ) |

851 ~ (10.7 ~ ) |

| (BH)max | kJ/m3 (MGOe) |

38 ~ 50 (4.8 ~ 6.2) |

49 ~ 60 (6.2 ~ 7.5) |

31 ~ 39 (3.9 ~ 4.9) |

39 ~ 49 (5.0 ~ 6.1) |

| μrec | - | 1.10 ~ 1.20 | 1.10 ~ 1.20 | 1.10 ~ 1.20 | 1.10 ~ 1.20 |

| α (23 ~ 120℃) |

% /℃ | -0.07 | -0.08 | -0.06 | -0.06 |

| β (23 ~ 120℃) |

% /℃ | -0.42 | -0.43 | -0.41 | -0.41 |

| Density | g/cm3 | 4.76 | 5.07 | 4.77 | 5.07 |

| Thermal Expansion Coefficient (20 ~ 100℃) |

10-6/℃ | MD : 1.7 TD : 2.1 |

MD : 1.6 TD : 2.0 |

MD : 1.7 TD : 2.1 |

MD : 1.5 TD : 2.0 |

| Flexural Strength | MPa (kgf/mm2) |

60 (6.2) |

47 (4.8) |

54 (5.6) |

40 (4.1) |

| Bending Elastic Modulus | MPa (kgf/mm2) |

24,800 (2,529) |

26,900 (2,744) |

24,200 (2,468) |

26,100 (2,662) |

| Ring Crushing Strength | MPa (kgf/mm2) |

84 (8.6) |

60 (6.2) |

77 (7.9) |

53 (5.4) |

| Hardness | HRM | 96 | 95 | 93 | - |

※Notes※

- Magnetic properties are measured after magnetization at 5 T.

- The data in this table are obtained from Daido's standard test pieces and do not represent guaranteed values.

- These values may vary depending on the magnet shape, dimensions, test conditions, and equipment. We recommend verifying the values using actual products.

- Guaranteed values can be established through consultation for specific shapes and sizes.

- The data are subject to change without notice.

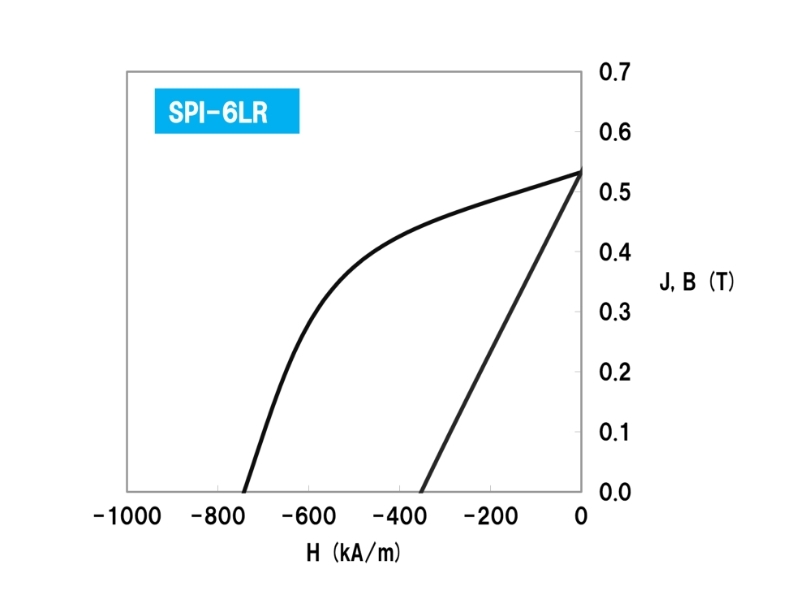

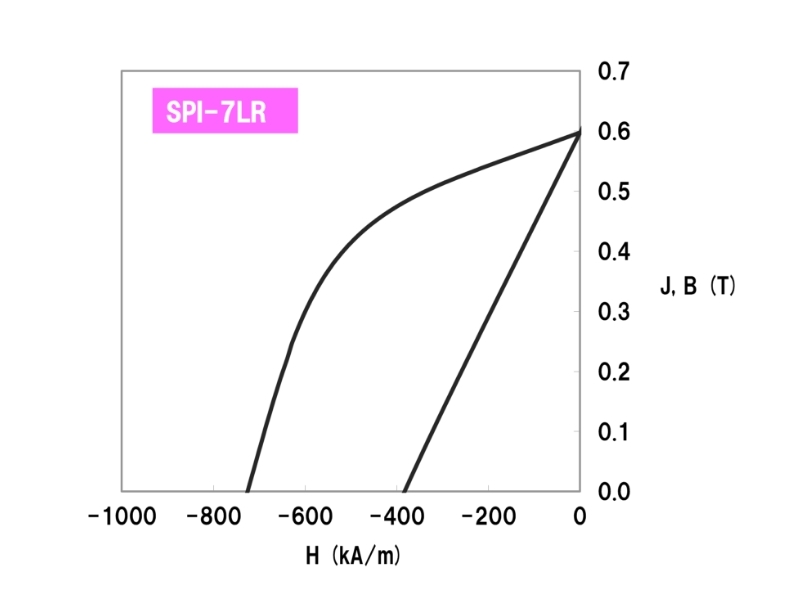

Demagnetization Curves of Injection-Molded Bonded Magnets at Elevated Temperatures

(23 ~ 150 ℃)