Original products

We develop original products that meet the needs of the market.

We can offer trial deposition using our sputtering machine and offer deposited samples.

【New】STARMESH®-γ1:Sputtring Target for Blackening Layer

| Applications | Blackening layer for Metal-mesh electrode-based touch panel |

| Type | Sputtering target |

| Feature |

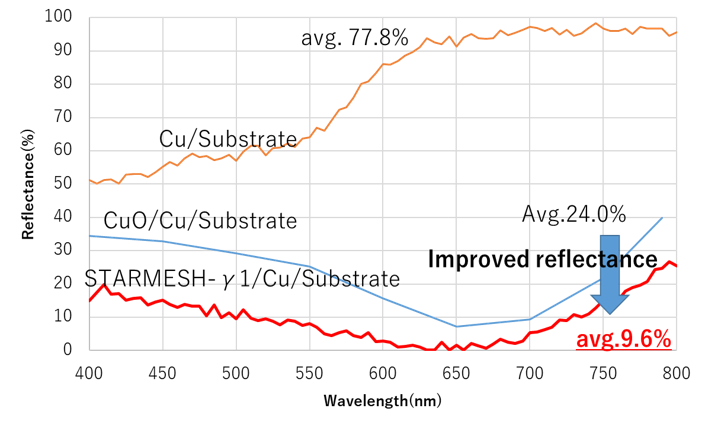

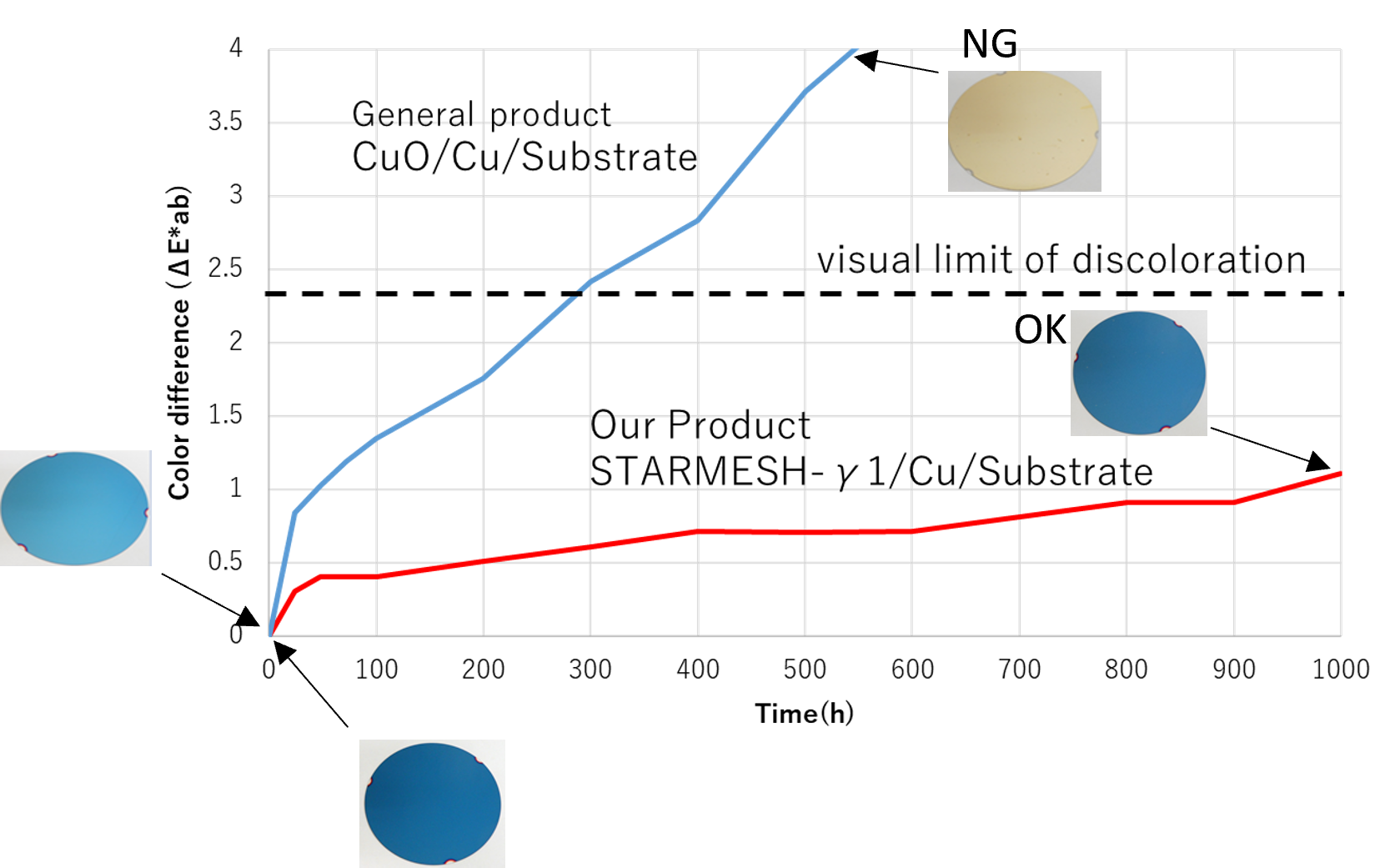

Low reflectance, etching resistance, and long-term discoloration resistance By stacking the blackening layer on Cu or Al wiring, the reflectance of the electrodes decreases. The blackened layer and conductive layer can be etched simultaneously using ferric chlorides.

Product appearance

Reflectance

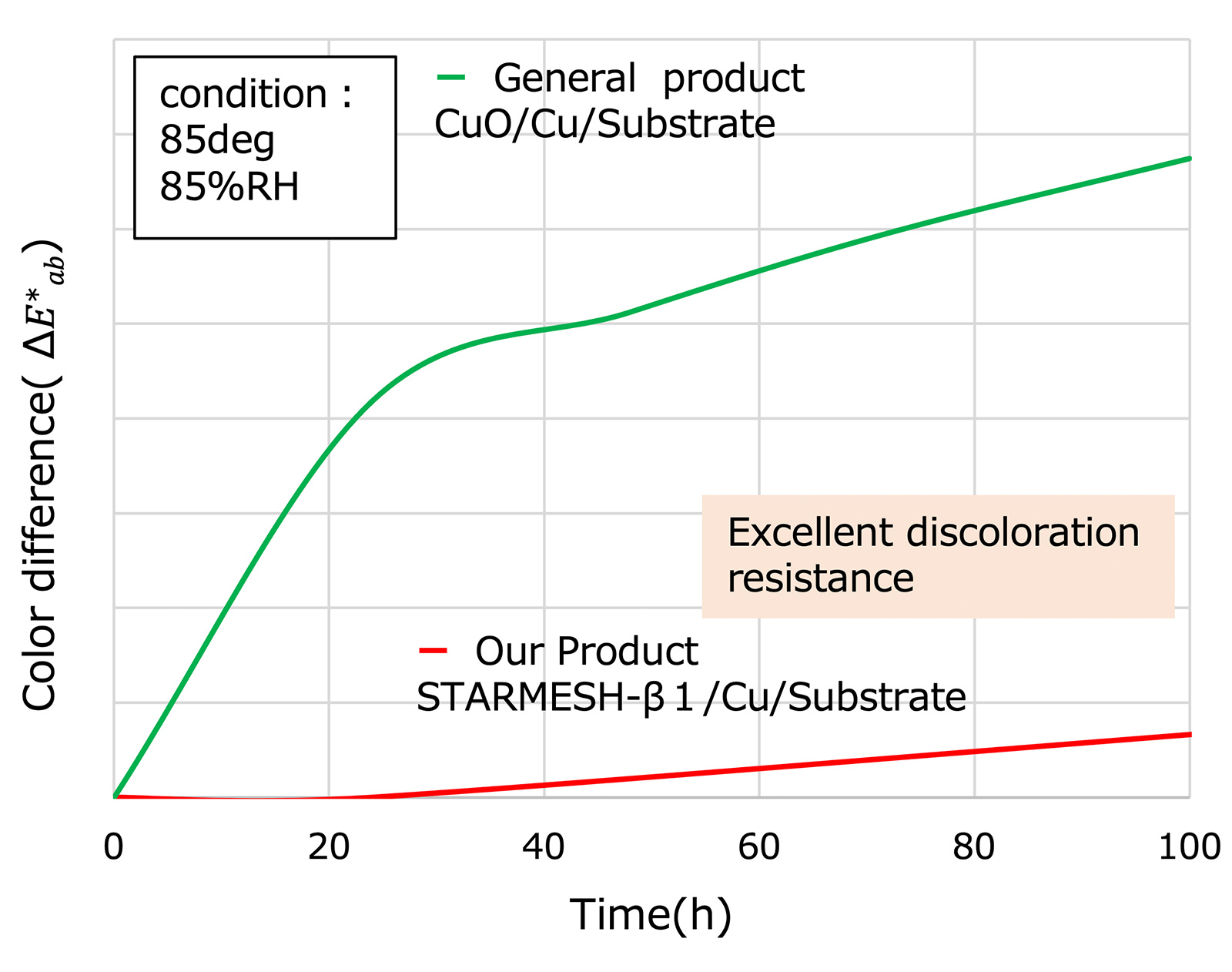

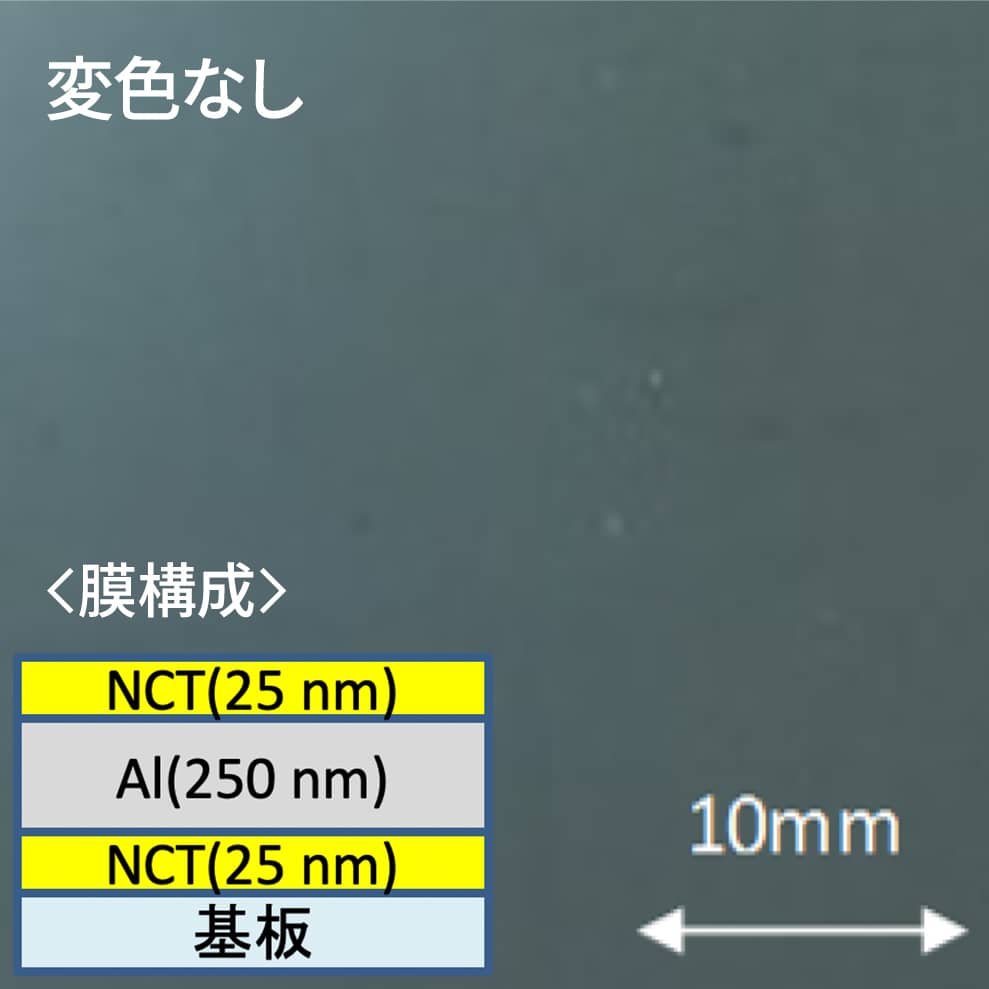

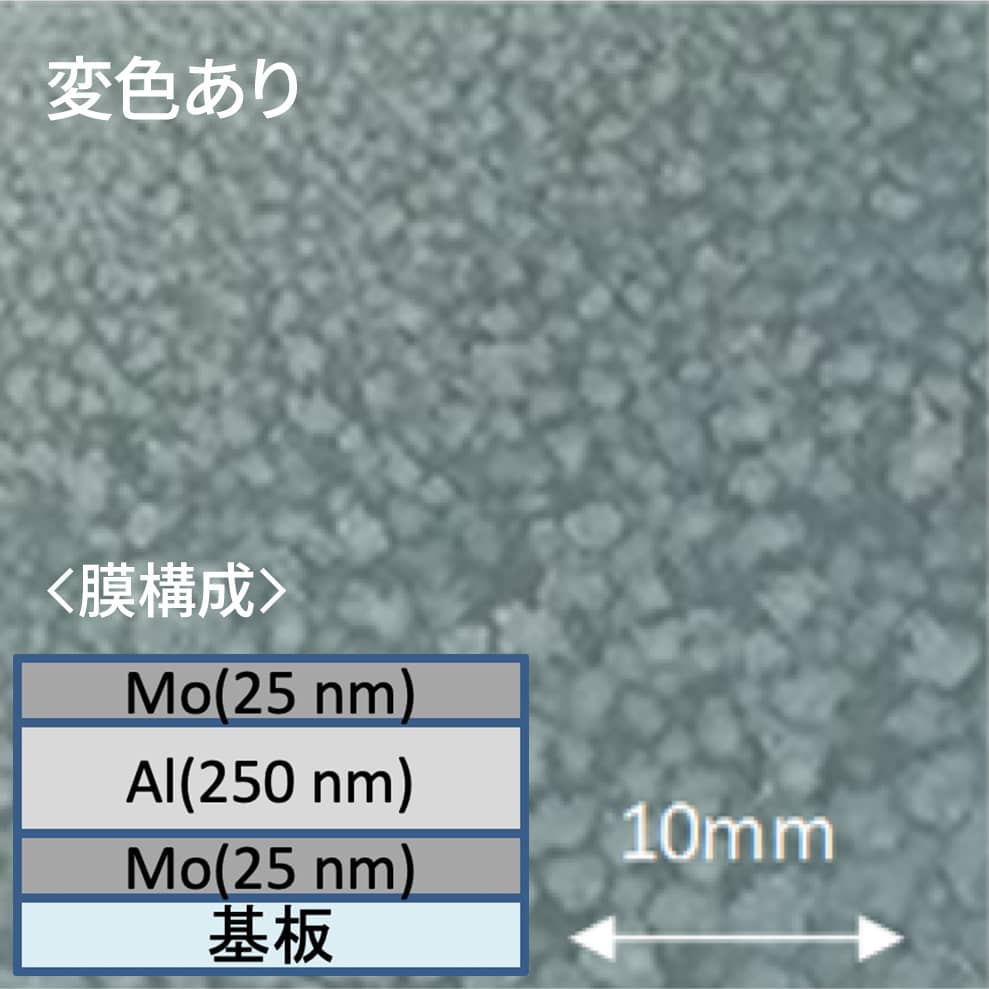

Discoloration Resistance

Etching conditions

Etchant :ferric chloride(1.5 wt%) temperature:35℃ Time :40s (Stationary)

|

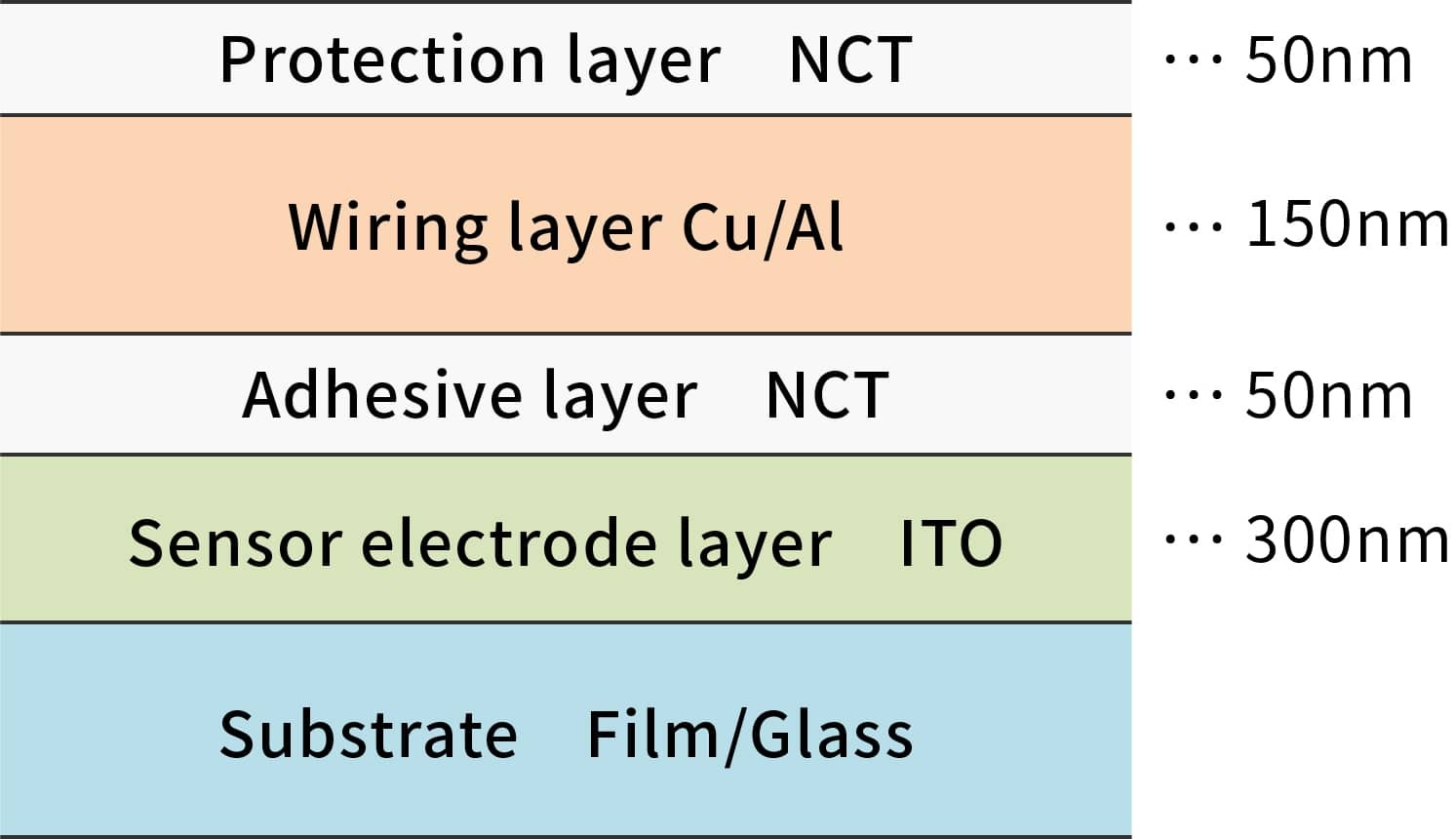

| Example of use |

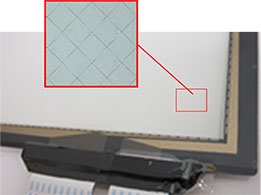

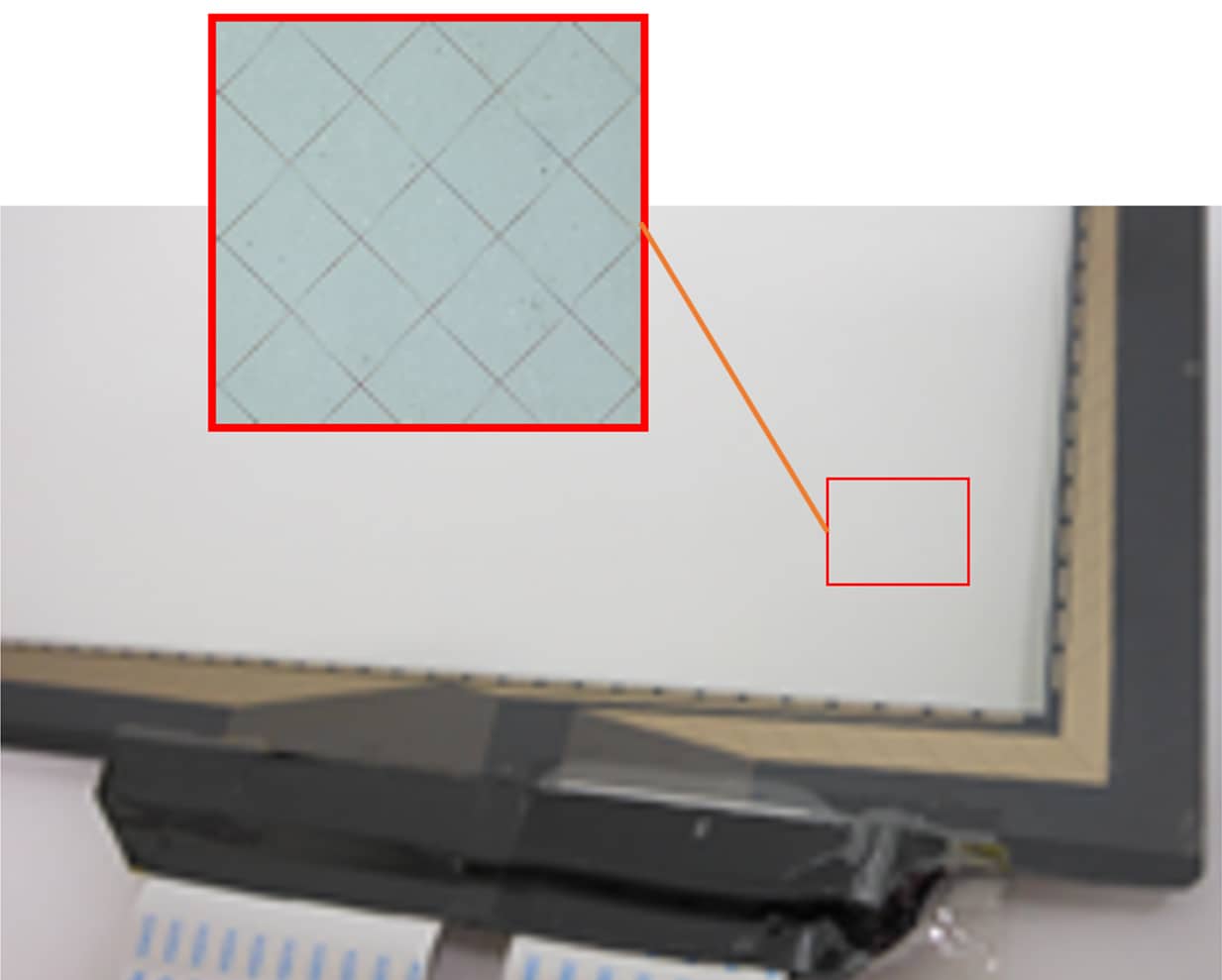

Metal-mesh Electorde-based Touch Panel

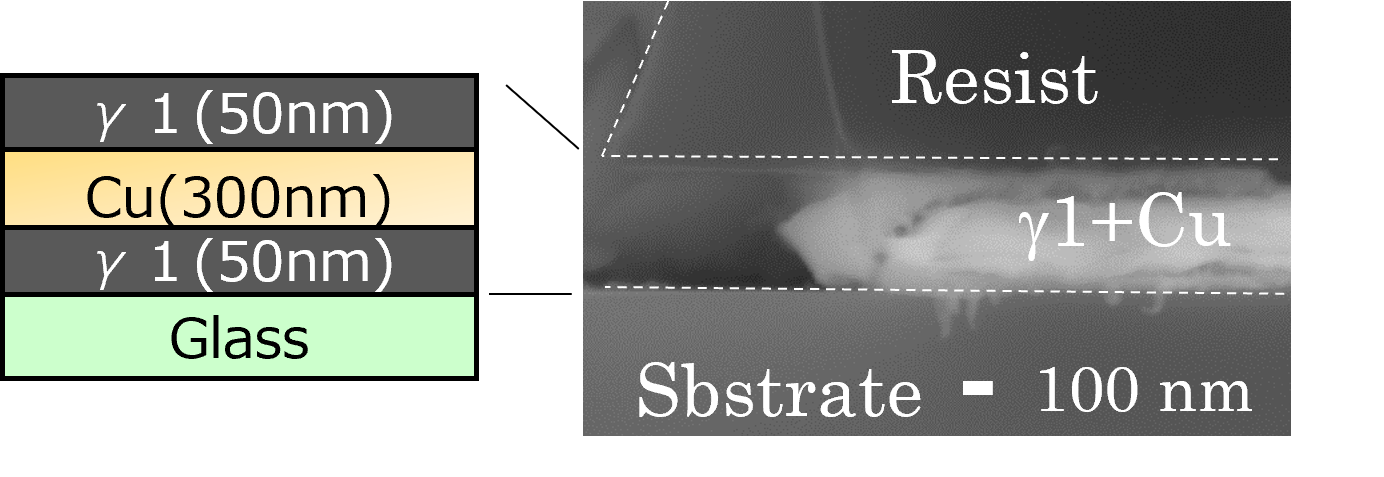

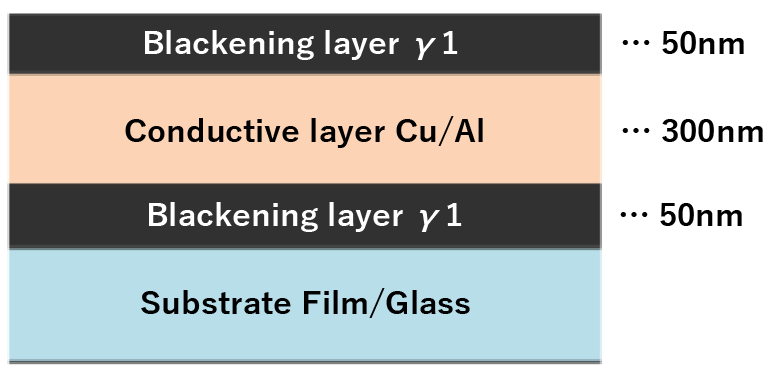

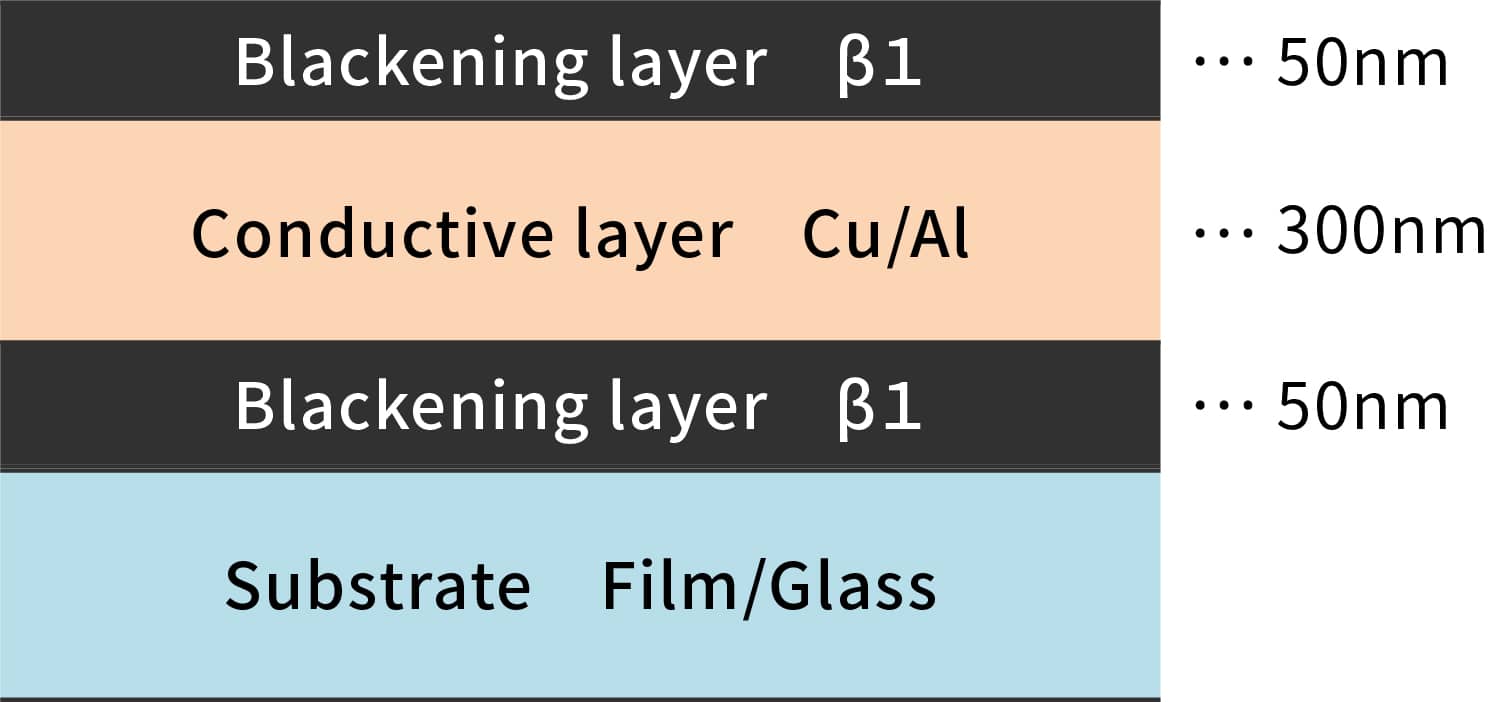

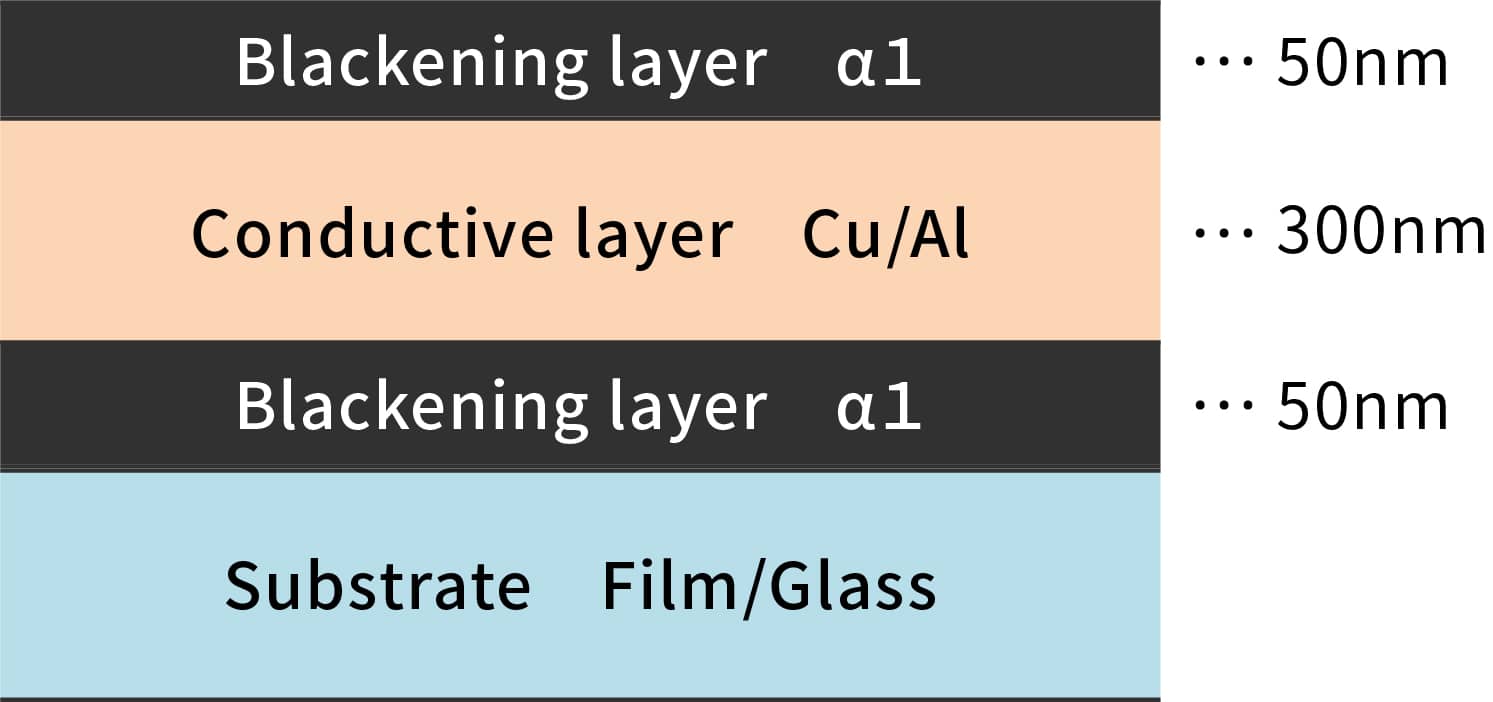

Cross section view of metal mesh Electrode

|

| Product introduction |

Technical Data :Denkiseiko 93th volume(2022) No.2 Development of STARMESH®-γ1 Target Material for Metal Mesh Blackening Film with Excellent Discoloration Resistance and Etching Properties(PDF:2,444KB) |

STARMESHTM-β1:Sputtering Target for Blackening Layer

| Applications | Blackening layer for Metal-mesh electrode-based touch panel |

| Type | Sputtering target |

| Features |

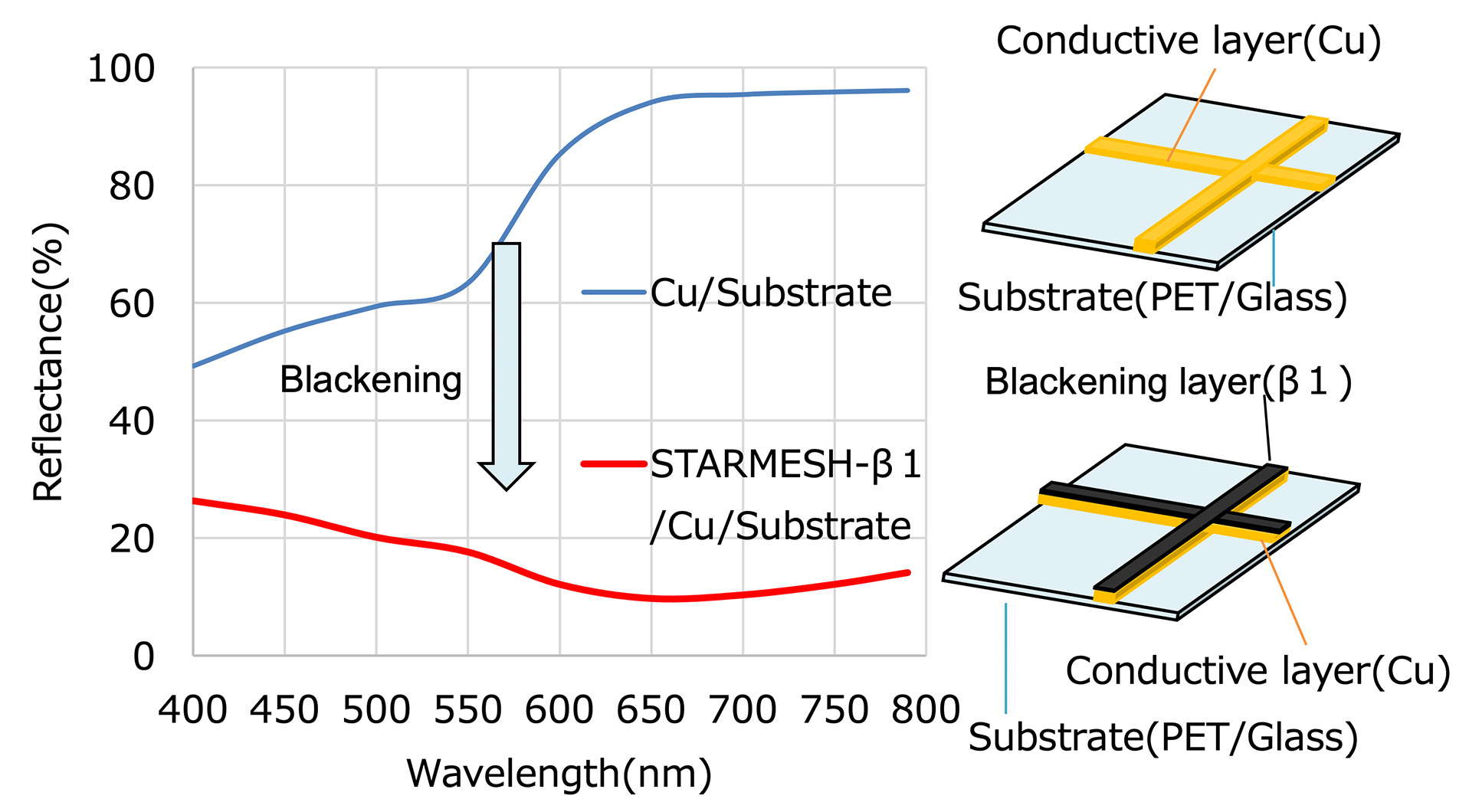

Low reflectance & Excellent discoloration resistance By stacking the blackening layer on Cu or Al wiring, the reflectance of the electrodes decreases.

Product appearance

Reflectance

Discoloration resistance

|

|

Example of use |

Metal-mesh Electrode-based Touch Panel

Cross section view of metal mesh electrode

|

| introduction | NEWS Development of the Sputtering Target "STARMESHTM-β1" for Blackening Layer with Excellent discoloration resistance |

STARMESHTM-α1:Sputtering Target for Blackening Layer

| Applications | Blackening layer for Metal-mesh electrode-based touch panel |

| Type | Sputtering target |

| Features |

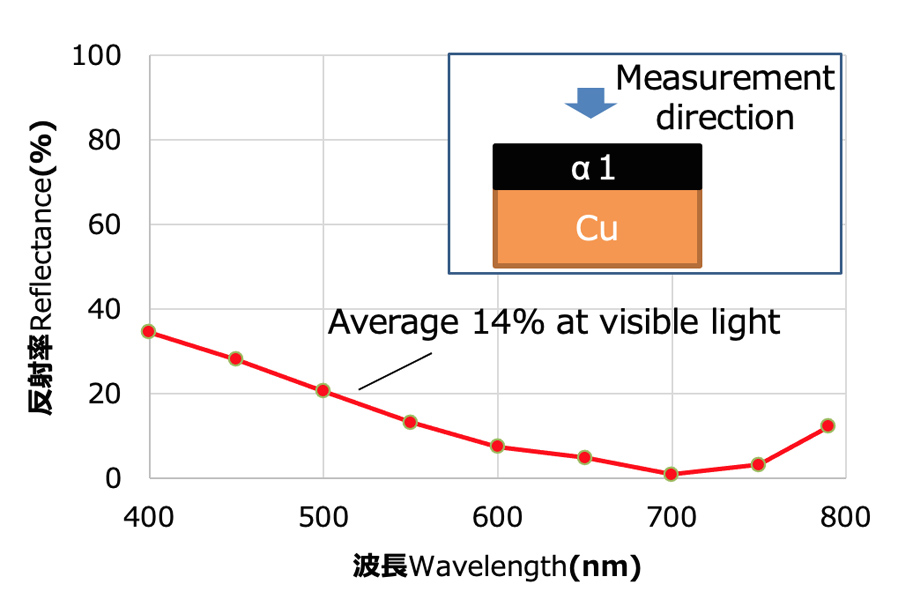

Low reflectance and Good etchantability By stacking the blackening layer on Cu or Al wiring, the reflectance of the electrodes decreases.

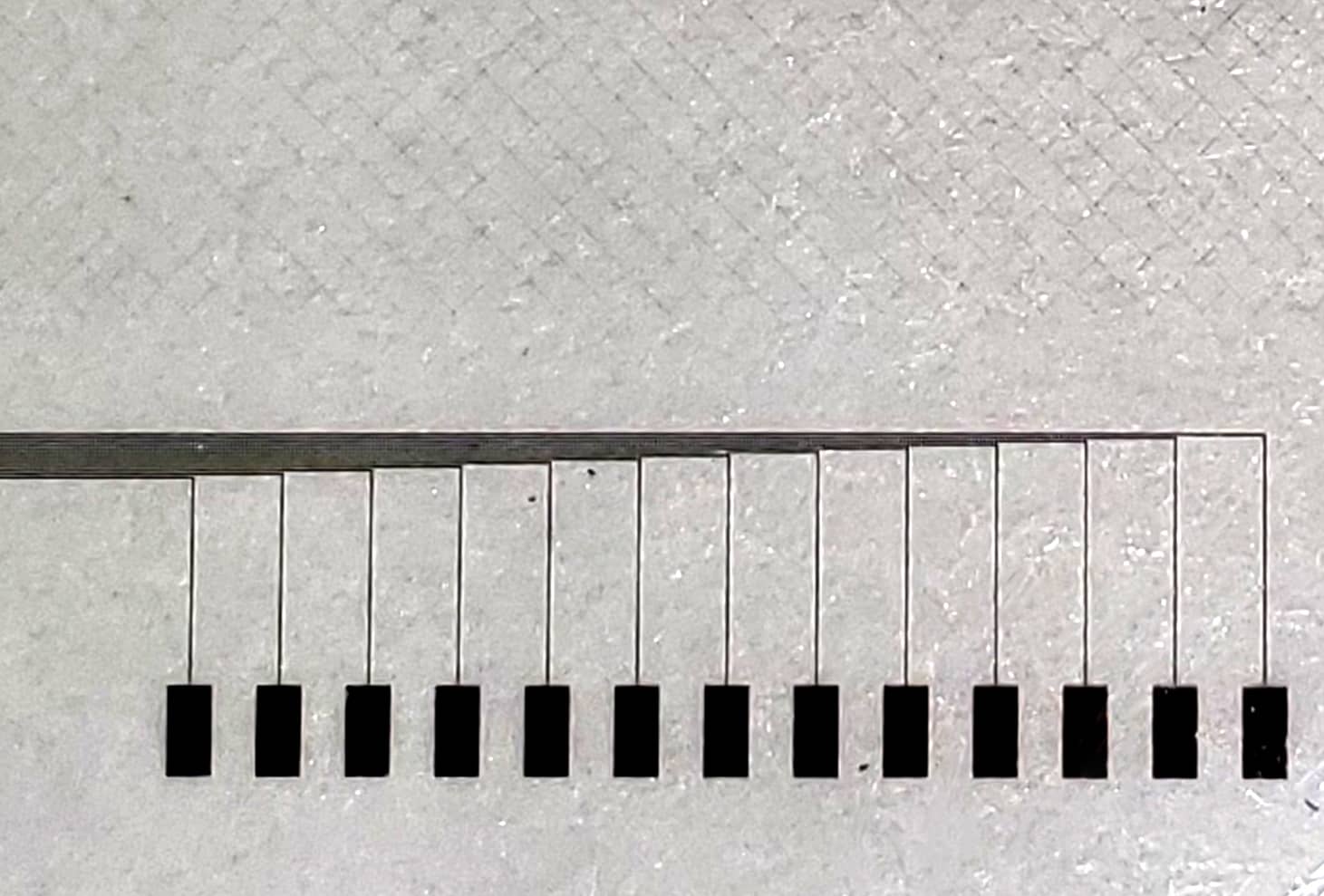

Product appearance

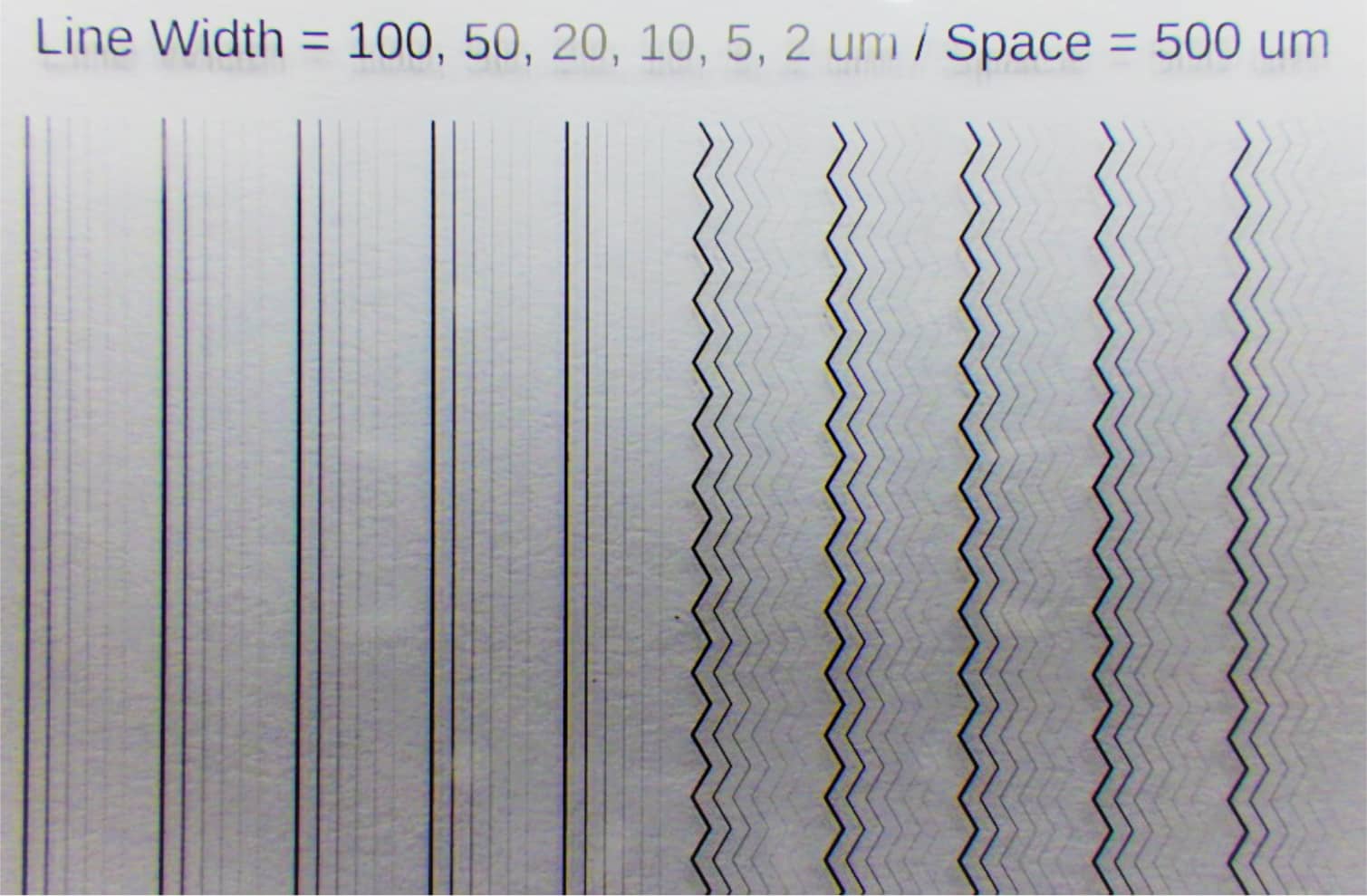

Patterned sample

(3μm at minimum Line width)

Reflectance

|

|

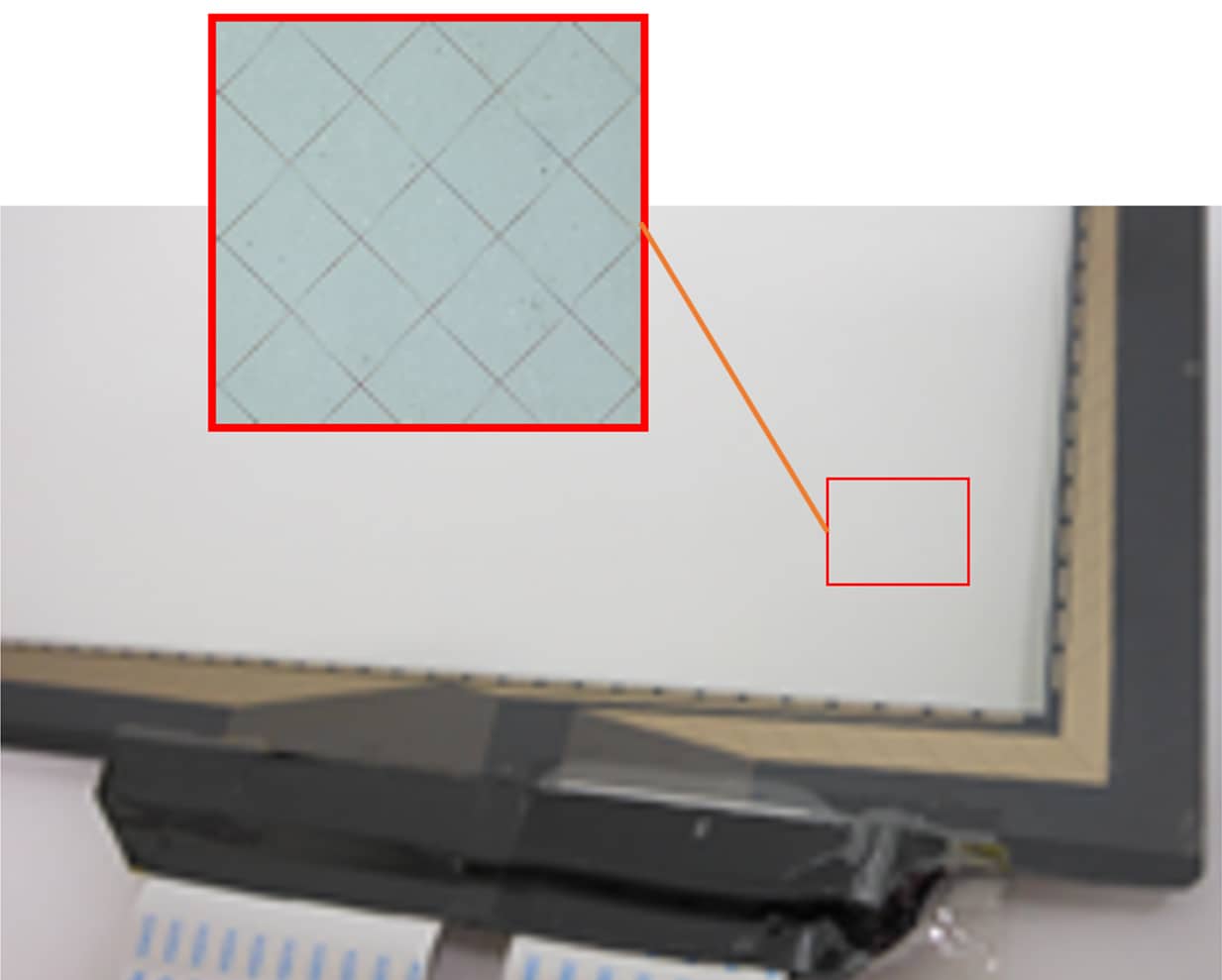

Example of use |

Metal-mesh Electrode-based Touch Panel

Cross section view of metal mesh electrode

|

NCT:Ni Alloy Sputtering Target for Protective Layer

| Applications | Protective layer for Al or Cu wiring |

| Type | Sputtering target |

| Features |

Excellent corrosion resistance and wet etchability As a protective film, it improves the corrosion resistance of Al or Cu wiring. Simultaneous etching of conductive layers and protective layer is possible using commercially available etchants.

Product appearance Our Product

Comparison material

Deposition appearance after Humidity test |

|

Example of use |

Protect layer for touch panel wiring

Cross section view of layers for touch panel

Patterned sample

(2μm at minimum Line width) |

Target materials

Sputtering targets, Ionplating targets and evaporation materials

Various types of target and evaporation materials are available from Daido to meet your application, manufacturing method and required performance needs. We promise to provide you with high-quality target and evaporation materials meeting your requirements for high purity, uniform composition, high density and low gas content.

| Main applications | Purity | Material | ||

|---|---|---|---|---|

| Magnet recording film | 3N~4N | Ni | Co | Fe |

| Ni-alloy | Co-alloy | Cr | ||

| Cr-alloy | ||||

| Display film | 3N~4N | Cr | Mo | Ta |

| Ag-alloy | ||||

|

Semiconductor film, Electronic device film |

3N~6N | Mo | Ta | W |

| Ti | Ni | |||

|

Magnet-Optical recording film |

3N | Gd-Fe-Co | Tb-Fe-Co | Al-Ti |

| Al-Cr | Al-V | |||

|

Decorative film, Surface-hardening film |

2N~3N | Ni-Cr-Mo | Zr | Hf |

| Ti-Al | Ti-Al-V | Cr | ||

| Ti | ||||

| Resistor film | 3N | Ni-Cr | Ni-V |

- Please feel free to consult us regarding requirements for materials, shapes, backing plate fabrication and bonding other than those shown above.

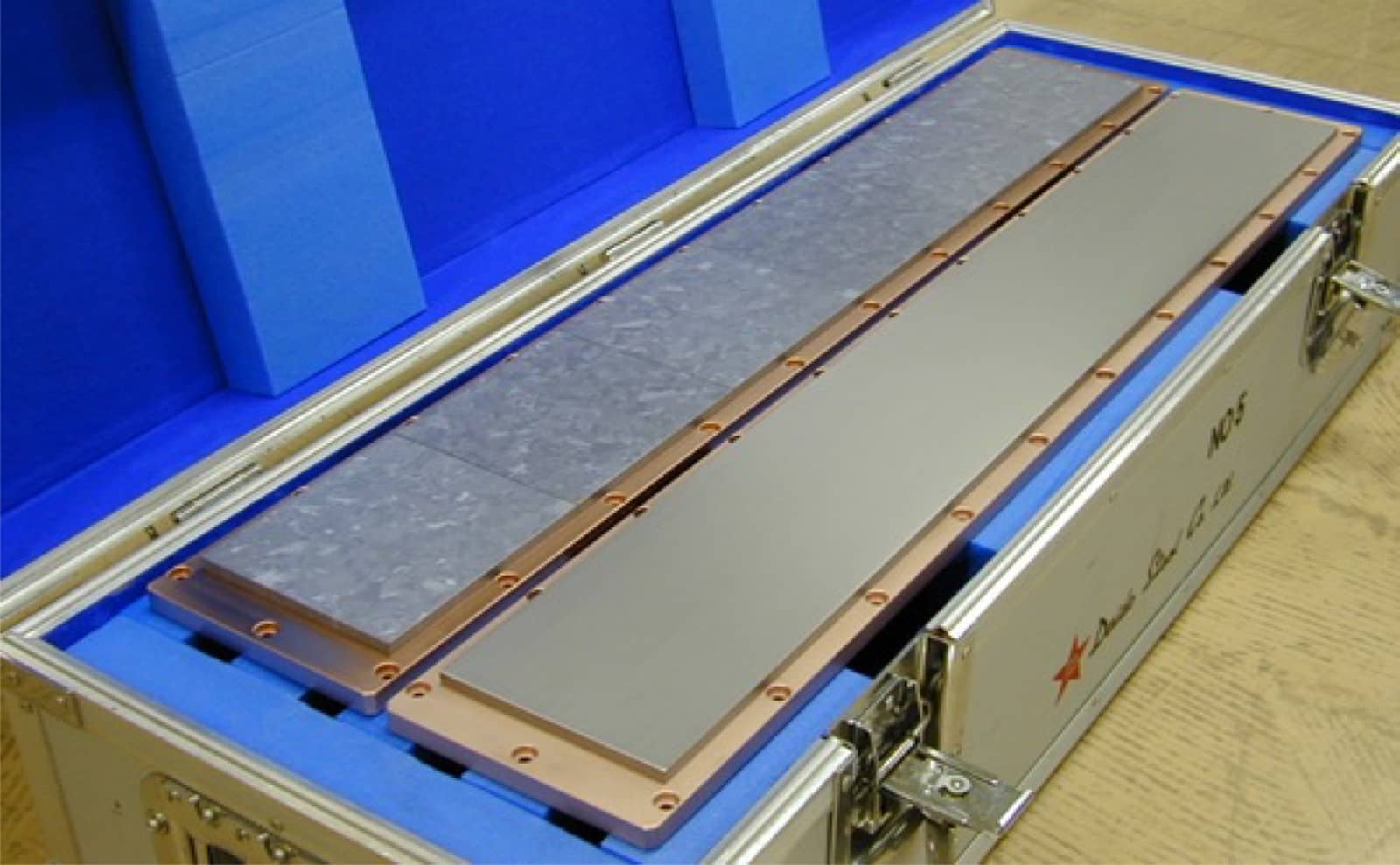

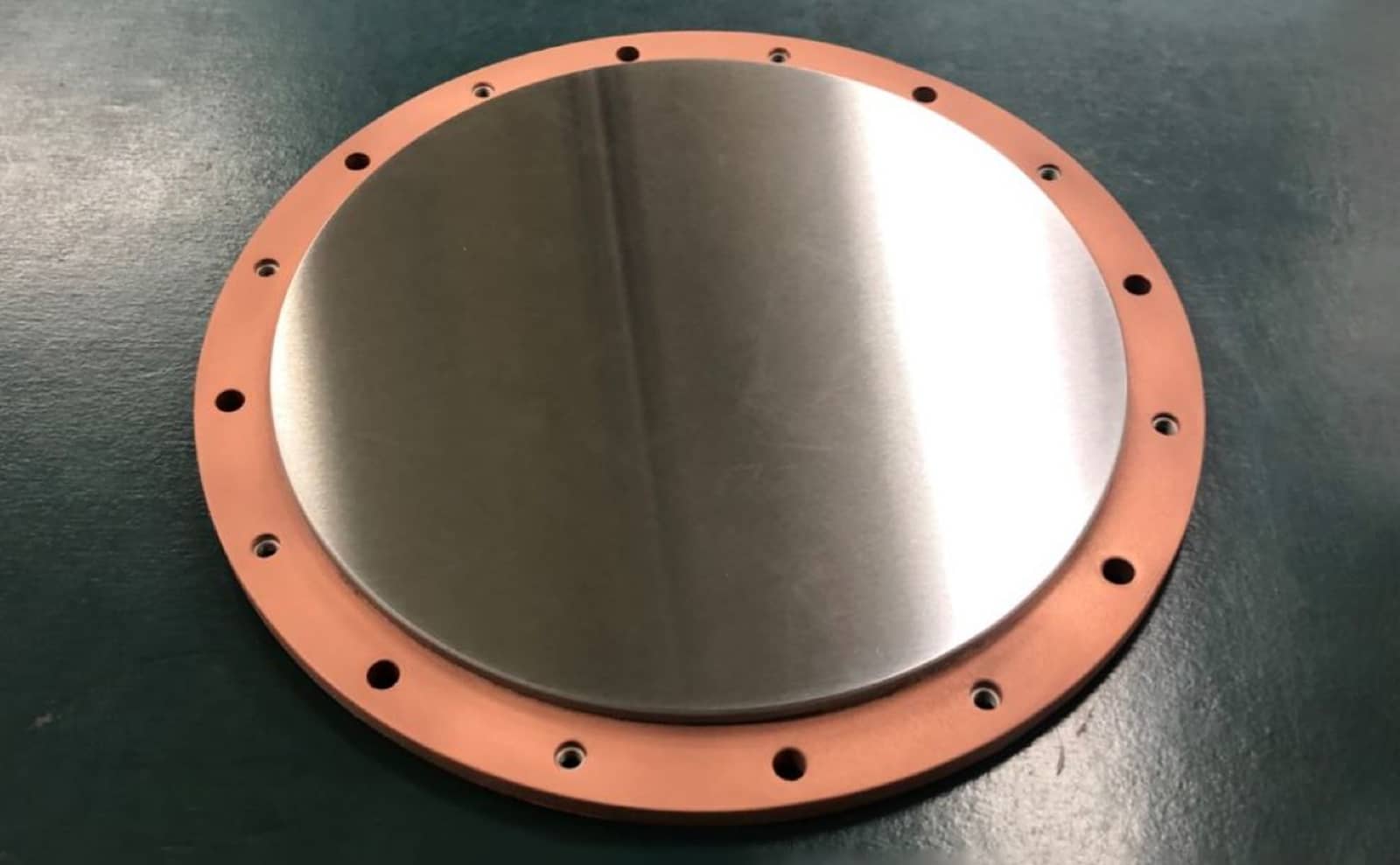

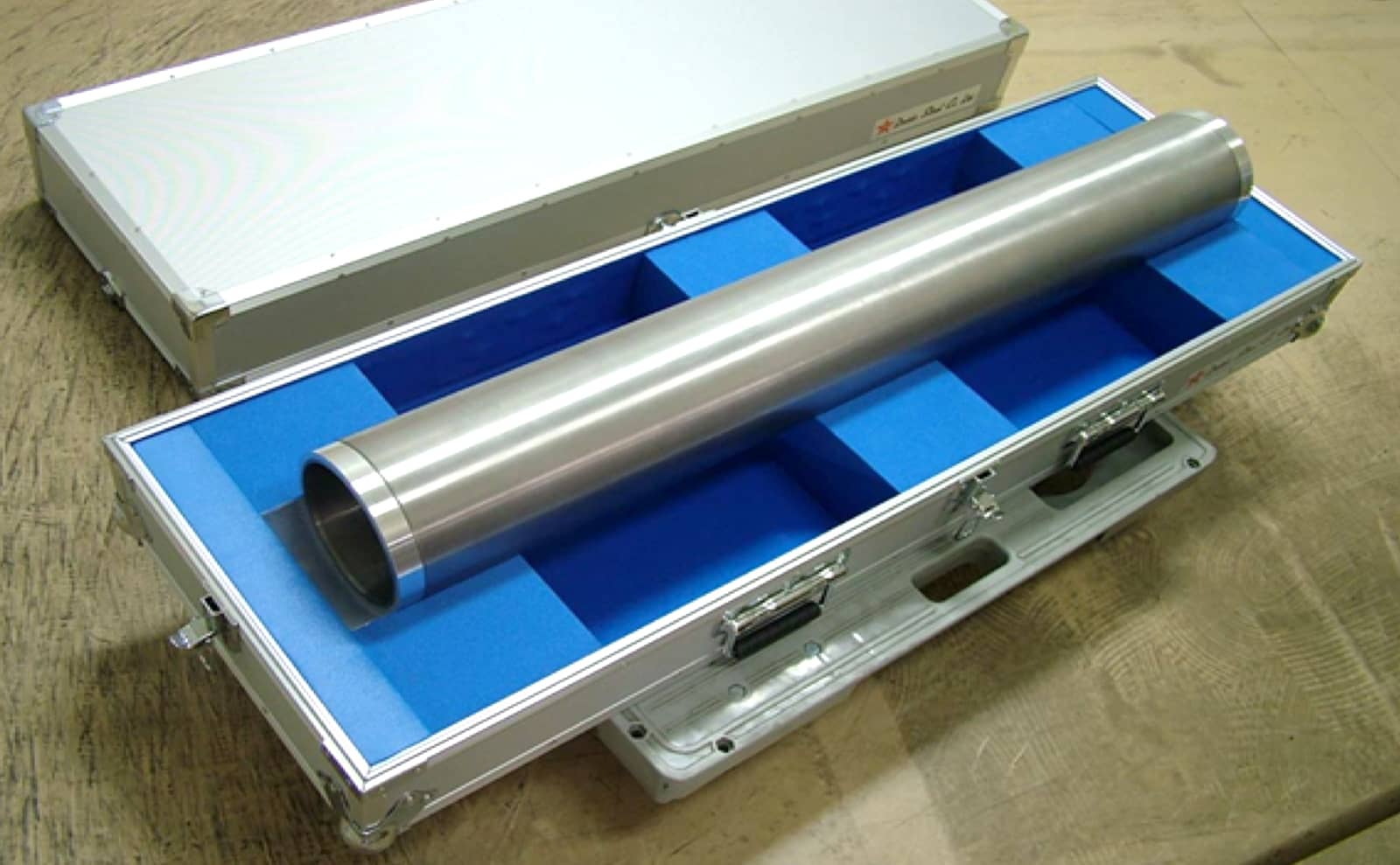

Product appearance

Width 50-300mm, Length300-3000mm

φ1~12inch/φ25~350㎜

Width 50-300mm, Length 500-2000mm

Example :φ50mm、10x10x10mm、φ13x10m